5 Common Mistakes to Avoid with IECEx-Approved Devices

5 Common Mistakes to Avoid with IECEx-Approved Devices

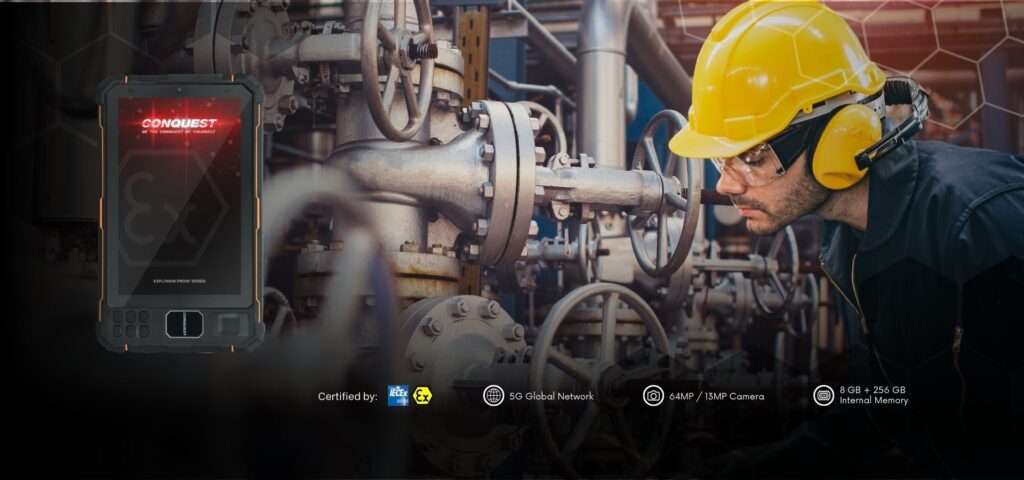

In hazardous industries such as oil and gas, petrochemicals, mining, and logistics, safety is not just a compliance requirement—it is a daily operational priority. One of the most critical safety measures is the use of IECEx-approved devices, which are designed and certified to function safely in explosive atmospheres.

IECEx certification ensures that devices meet the highest international standards for intrinsic safety and explosion protection. Yet, despite the importance of compliance, organizations often make costly mistakes when choosing, deploying, or maintaining these devices. These oversights can lead to safety risks, regulatory violations, and operational downtime.

To help you protect your people, assets, and reputation, we’ve identified the five most common mistakes companies make with IECEx-approved devices—and, more importantly, how to avoid them.

Mistake #1: Ignoring Certification Details

One of the most common pitfalls is assuming that a device labeled “certified” automatically meets every standard relevant to your operations. In reality, certification is complex.

- IECEx vs. ATEX vs. UL: While IECEx certification is globally recognized, ATEX applies within the European Union, and UL standards apply in North America. A device may meet one certification but not the others.

- Multi-standard certification: In global operations, devices often need to carry more than one approval to ensure compliance across regions.

Why it matters: A misunderstanding here can result in non-compliant equipment being deployed in hazardous zones, creating unnecessary risks and possible legal liabilities.

Best Practice: Always review the full certification scope on the device datasheet, check for official markings, and confirm that it meets IECEx requirements relevant to your hazardous zones. If your operation spans multiple regions, choose multi-certified rugged devices to simplify compliance.

Mistake #2: Choosing the Wrong Device for the Hazard Zone

Hazardous areas are divided into zones based on the likelihood of explosive gases or dust being present. IECEx certification defines three main gas zones:

- Zone 0: Explosive atmosphere is present continuously or for long periods.

- Zone 1: Explosive atmosphere is likely to occur during normal operation.

- Zone 2: Explosive atmosphere is unlikely or only present for short durations.

The mistake: Companies sometimes deploy a device rated for Zone 2 in a Zone 0 environment. While both may be IECEx-approved, the certification scope is not interchangeable. This misstep leads to non-compliance and increased risks.

Why it matters: Using the wrong classification can compromise worker safety, void certifications, and attract penalties from regulatory bodies.

Best Practice: Match each device precisely to the zone classification of the intended environment. For example, Conquest IECEx-certified smartphones are available with ratings for different zones, giving organizations the flexibility to choose the correct device for the right environment.

Mistake #3: Overlooking Environmental Resistance

IECEx certification ensures a device can operate safely in explosive atmospheres, but it does not guarantee performance in extreme environmental conditions. Many organizations focus solely on explosion-proof requirements while neglecting factors such as:

- Temperature extremes (very hot or cold environments)

- Dust and water exposure (measured by IP ratings)

- Shock and vibration (important in construction, mining, or offshore work)

- Chemical resistance (corrosive industrial environments)

The mistake: Purchasing a certified device that lacks adequate ruggedness for the real-world conditions where it will be deployed.

Why it matters: A device that fails under environmental stress not only disrupts operations but can also pose safety risks if it malfunctions during critical tasks.

Best Practice: Look for devices that combine IECEx certification with rugged engineering—for example, military-grade durability, IP68/IP69 ratings, and proven resistance to dust, chemicals, and shock. This ensures long-term reliability in demanding industries.

Mistake #4: Neglecting Battery and Power Safety

Batteries are one of the most overlooked aspects of device safety. In hazardous environments, even a small energy surge can ignite flammable gases or dust.

The mistake: Using non-approved or aftermarket batteries in IECEx-certified devices. While the device itself may be certified, replacing the battery with an uncertified component undermines its safety.

Why it matters: Batteries are a common ignition source. If not intrinsically safe, they can generate excess heat, sparks, or overcharge risks.

Best Practice:

- Only use manufacturer-approved, intrinsically safe batteries with IECEx devices.

- Consider devices with hot-swappable batteries, which allow safe replacement without shutting down operations.

- Train staff to inspect and replace batteries according to manufacturer guidelines.

With Conquest rugged smartphones, safety-approved battery systems ensure reliable operation in Zone 1 and Zone 2 environments, without compromising on performance.

Mistake #5: Failing to Plan for Long-Term Maintenance

Compliance is not a one-time event. IECEx certification requires ongoing attention throughout a device’s lifecycle.

The mistake: Deploying IECEx-approved devices without considering maintenance schedules, documentation, or certification renewals.

Why it matters: Over time, components can degrade, updates may be required, and certification rules may evolve. Without proper maintenance, a once-compliant device can become a compliance liability.

Best Practice:

- Partner with a supplier that offers after-sales support, spare parts, and technical assistance.

- Maintain clear records of certifications and inspections.

- Ensure that devices remain compliant throughout their service life, especially if used across multiple hazardous zones.

Conquest supports clients not just with rugged devices, but also with ongoing service and technical expertise to keep operations compliant and efficient.

Mistake #6: Overlooking Training and User Awareness

Even the most advanced IECEx-approved devices can only perform as intended when used correctly. Too often, companies focus on procurement and certification while neglecting to train employees on proper device handling, inspection, and usage protocols.

The mistake: Assuming that certification alone eliminates the need for user training. Workers may unknowingly bypass safety procedures, mishandle equipment, or use uncertified accessories.

Why it matters: Human error remains one of the leading causes of incidents in hazardous areas. A device may be safe by design, but improper usage—such as charging in an unsafe zone, swapping batteries incorrectly, or ignoring enclosure warnings—can compromise safety and compliance.

Best Practice:

- Provide regular training sessions on safe use of IECEx devices.

- Include instruction on zone classifications, proper charging, and accessory use.

- Reinforce awareness with on-site safety signage and quick-reference guides.

- Partner with a supplier that offers educational resources and customer support to keep teams informed and compliant.

At Conquest, we believe safety is a combination of rugged technology and human vigilance. That’s why our commitment extends beyond devices—we support organizations with resources that empower workers to use IECEx-approved smartphones safely and effectively.

Zone 1/Zone 2 Devices: Technology Trends for Risk Reduction highlight the latest innovations that enhance safety in hazardous areas, reduce risks, and ensure compliance with ATEX standards.

Conclusion

IECEx-approved devices are essential for ensuring safety in hazardous environments, but simply buying a certified product is not enough. By avoiding these five common mistakes—ignoring certification details, misapplying devices to the wrong zone, overlooking environmental resistance, neglecting battery safety, and failing to plan for maintenance—organizations can protect their workforce, meet regulatory obligations, and maximize their investment.

Safety, compliance, and reliability should never be compromised. When choosing devices, always partner with a provider who understands both the regulatory landscape and the practical challenges of hazardous industries.

Ensure communication is smart, safe, and secure with Conquest IECEx-Certified Smartphones. Our rugged devices are engineered to withstand extreme environments while meeting the strictest international safety standards.

From oil & gas to logistics and manufacturing, Conquest provides reliable, compliant, and durable solutions for industries where failure is not an option.

Contact us today to explore our range of IECEx-approved smartphones or request a free consultation.

Understanding ATEX zones is vital for industrial safety. These zones classify areas by explosion risk, helping choose the right equipment to prevent hazards.

More Interesting Posts

How Conquest EX202 Enhances Operational Efficiency with Built-In Tools

Enhancing Worker Safety with Conquest EX201’s Satellite Communication

Explosion Proof Smartphones in Malaysia for Petrochemical Industry