Understanding Temperature Sensors: Working Principles, Types, Applications & Choosing the Right One

If you’re looking to understand what a temperature sensor is, how it works, and which type suits your needs best — you’re in the right place.

From industrial plants to everyday electronics, temperature sensors play a crucial role in maintaining safety, performance, and automation. Whether you’re designing a smart system or working in hazardous zones, selecting the right sensor is critical for reliable temperature monitoring. In this blog, we’ll explore the different types of temperature sensors, how they function, where they’re used, and how to choose the best one for your application — all with a focus on rugged environments.

Stay with us as we break down complex technical concepts into easy-to-understand insights, and introduce powerful industrial solutions, including sensor-ready rugged devices from Conquest Explosion Proof.

What is a Temperature Sensor?

A temperature sensor is a device that detects thermal changes and converts them into signals readable by control systems, instruments, or digital platforms. These devices are widely used in industrial processes, consumer products, and scientific equipment for real-time temperature tracking.

Unlike traditional glass thermometers, a temperature sensor enables automatic monitoring and response — whether in a refinery, warehouse, smart home, or vehicle. It plays a vital role in maintaining safe operating conditions and optimizing performance.

Key Characteristics of a Temperature Sensor:

- Monitors environmental or system temperature

- Sends signals to control units, alarms, or software

- Supports automation and preventive maintenance

- Reduces human error in critical applications

Temperature sensors can vary in accuracy, speed, range, and durability — making it essential to understand their types and applications before choosing one.

How Does a Temperature Sensor Work?

A temperature sensor operates by detecting changes in physical properties (like resistance or voltage) when the surrounding temperature changes. It then converts these changes into electrical signals, which can be interpreted by connected systems or devices.

Here’s how the main types function:

- RTDs (Resistance Temperature Detectors): These sensors use pure metals, commonly platinum. As the temperature rises, so does the resistance. They are accurate and stable over long periods.

- Thermistors: These are made from ceramic or polymer materials. They are extremely responsive to small temperature changes. Thermistors come in two forms: NTC (resistance drops with rising temperature) and PTC (resistance increases).

- Thermocouples: Made by joining two different metals. When heated, a voltage is generated at the junction. They are widely used in high-temperature environments due to their wide range and fast response time.

- Semiconductor Sensors: Found in integrated circuits. These devices output a voltage or digital signal that changes with temperature. They’re ideal for compact, low-power applications but are limited in temperature range.

Each type is engineered to perform best in specific operating conditions — from delicate lab instruments to rugged industrial machinery.

Types of Temperature Sensors

Thermocouples

- Work based on voltage generated by heat at a metal junction

- Can measure very high temperatures, up to 1750°C

- Common in heavy-duty environments like metal foundries, aerospace, and petrochemical plants

- Durable and fast-responding, but offer moderate accuracy

For extreme conditions, ATEX phones are often paired with thermocouples for rugged environments.

RTDs (Resistance Temperature Detectors)

- Use resistance change in metals like platinum to measure temperature

- Provide very precise and stable readings over time

- Ideal for processes where accuracy is critical, such as in pharmaceutical or automotive industries

- More expensive than thermocouples, but worth the investment for stability

Consider integrating with an intrinsically safe mobile phone for enhanced durability.

Thermistors

- Offer rapid response to temperature changes

- Cost-effective and compact

- Suitable for applications like air conditioning systems, battery packs, and medical devices

- Best used in limited temperature ranges, typically -100°C to 300°C

Semiconductor Sensors

- Integrated into circuit boards and microcontrollers

- Deliver digital or analog output

- Often used in consumer electronics, wearables, and computer systems

- Not ideal for extreme temperatures or rugged environments

Vibrating Wire and Custom OEM Sensors

- Specialized sensors such as vibrating wire types are used in geotechnical and structural health monitoring

- OEM temperature sensors are tailored to client-specific industrial needs

- Manufacturers like Encardio and Ashcroft offer bespoke solutions for high-risk zones

Each type of temperature sensor plays a distinct role in ensuring safe and reliable operations across a wide range of industries.

Applications of Temperature Sensors

Temperature sensors are embedded into the infrastructure of nearly every industry. Here are some common real-world applications:

- Industrial Processes: Used to control heating elements, monitor chemical reactions, and ensure equipment safety

- Construction & Infrastructure: Monitor concrete curing, tunnel temperatures, and site conditions

- Oil & Gas: Ensure thermal safety in rigs, pipelines, and storage units

- Manufacturing: Track machine temperature to prevent overheating and optimize product quality

- Healthcare: Maintain cold chain storage of medications, monitor patient conditions

- Consumer Electronics: Control temperature in laptops, smartphones, smart thermostats, and other devices

- Food & Beverage: Maintain correct storage and processing temperatures to meet hygiene regulations

Each application places different demands on the temperature sensor, requiring engineers to choose based on accuracy, durability, and response speed.

How to Choose the Right Temperature Sensor

When selecting a temperature sensor, consider the following key criteria:

- Accuracy: RTDs offer the highest accuracy, while thermocouples offer broader ranges with lower precision.

- Response Time: Thermistors are highly responsive, making them suitable for rapid changes in temperature.

- Environmental Conditions: For high-temperature or corrosive environments, thermocouples are often the best choice.

- Sensor Output Type: Choose between analog or digital signals depending on your data collection system.

- Budget and Longevity: Thermistors are affordable but may degrade faster, while RTDs are more stable but come at a higher cost.

Quick Comparison by Sensor Type:

- RTDs: High accuracy, stable, used in clean industrial applications

- Thermocouples: Rugged, wide range, lower cost, slightly less precise

- Thermistors: Fast, cost-effective, ideal for moderate environments

- Semiconductors: Low power, compact, best for electronic

Rugged Sensor Integration in Harsh Industrial Environments

In many real-world industrial environments, temperature sensors are only as effective as the system they’re connected to. When working in extreme or hazardous zones — such as oil refineries, mining shafts, or chemical plants — traditional smartphones and handheld devices fail to withstand the elements.

This is where rugged mobile devices step in.

Why Rugged Devices Matter:

- Designed to withstand high/low temperatures, water, dust, and shock

- Certified for use in explosive and hazardous areas (ATEX/IECEx)

- Support sensor integrations via Bluetooth, USB, or software platforms

- Enable real-time monitoring and data transmission even in remote locations

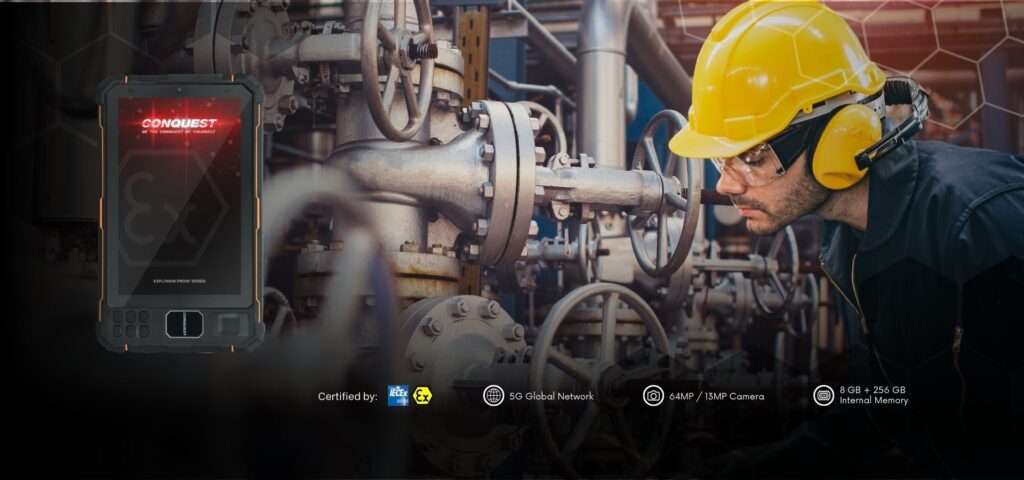

Brands like Conquest offer ATEX-certified rugged smartphones built specifically for field engineers, inspectors, and operators who rely on sensor-driven data to make decisions in real time.

Powering Field Operations with Conquest

Conquest smartphones aren’t just tough — they’re intelligent tools designed for demanding industrial tasks. If you’re using a temperature sensor in a hazardous setting, you need a mobile device that matches your sensor’s reliability and durability.

Conquest Devices Offer:

- ATEX & IECEx certifications for explosive environments

- Waterproof, shockproof, and dustproof construction

- Support for sensor integration, data logging, and industrial software

- Proven performance in extreme use cases — from China Railway to CHEMCHINA

Looking for a device that can withstand your most extreme work environments while supporting smart temperature monitoring solutions? Explore Conquest’s ATEX-certified smartphones — engineered for safety, built for performance.

Conclusion

From medical labs to manufacturing plants and underground tunnels, temperature sensors are an integral part of modern operations. Choosing the right one ensures safe, precise, and efficient processes. Whether you need high accuracy, wide range, or rugged compatibility, there is a sensor designed for your application.

But your job doesn’t end with the sensor. It’s just as important to have the right mobile technology to gather and manage that data effectively in the field.

That’s why rugged mobile solutions from Conquest play such a critical role — offering reliability where it matters most.

Frequently Asked Questions

A temperature sensor is used to measure heat or thermal energy and convert it into readable signals for monitoring and control across industries.

The main types include RTDs, thermistors, thermocouples, semiconductor sensors, and specialized OEM/vibrating wire sensors.

Thermocouples are best for high-temperature applications due to their broad range and durability.

Use rugged smartphones or tablets with sensor-compatible ports, Bluetooth, or dedicated industrial software platforms.

Yes, but you must use certified sensors and ATEX/IECEx-approved devices like those from Conquest.

Yes. RTDs offer superior long-term accuracy and stability, while thermistors respond faster but may drift over time.

In consumer electronics, like smartphones, gaming consoles, and wearables, where compact size and low power are important.

Standard devices can fail in harsh environments. Rugged phones like those from Conquest are designed to operate safely with sensors in extreme conditions.

More Interesting Posts

Enhancing Worker Safety with Conquest EX201’s Satellite Communication

Explosion Proof Smartphones in Malaysia for Petrochemical Industry