ATEX and IECEx Certifications Explained: What You Need to Know for Industrial Devices

If your business operates in industries such as oil and gas, chemical processing, mining, or logistics, you’ve probably heard of ATEX and IECEx certifications. These certifications are not just technical labels; they are critical safety standards that determine whether a device can be safely used in hazardous environments where explosive gases, vapors, or dust may be present. In short, if your device doesn’t carry the right certification, it could pose a serious risk to safety, compliance, and operations.

This article explains what ATEX and IECEx certifications mean, how they differ, why they matter for industrial devices, and what you should consider when choosing certified equipment. By the end, you’ll know exactly why rugged and intrinsically safe devices—like those from Conquest—play a vital role in keeping workers safe while improving productivity in hazardous environments.

What Are Hazardous Environments?

A hazardous environment is any workplace where flammable gases, vapors, or dusts are present in enough concentration to ignite or explode. Examples include:

- Oil and gas drilling platforms

- Chemical manufacturing plants

- Refineries and petrochemical facilities

- Pharmaceutical plants

- Mining operations

- Grain silos and food production facilities

In these settings, even something as small as a spark from a mobile phone, a hot surface, or a static discharge can ignite an explosion. That’s why strict international standards like ATEX and IECEx exist—to make sure the devices workers use are designed to prevent accidents.

What Is ATEX Certification?

ATEX comes from the French term “Appareils destinés à être utilisés en ATmosphères EXplosibles” (equipment intended for use in explosive atmospheres).

- Origin: ATEX is a European Union directive.

- Focus: It applies to electrical and non-electrical equipment used in explosive atmospheres.

- Key Directive Numbers: ATEX 2014/34/EU (for equipment) and ATEX 1999/92/EC (for workplace safety).

- Regions Covered: European Union and countries that follow EU regulations.

Devices with ATEX certification are tested to ensure they won’t trigger explosions under defined hazardous conditions. This includes measures like preventing sparks, controlling surface temperature, and containing any internal ignition.

Example

An ATEX-certified smartphone can be used safely in a gas refinery in France or Germany, where EU law demands compliance with ATEX standards.

What Is IECEx Certification?

IECEx stands for the International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres.

- Origin: Global standard managed by the IEC.

- Focus: Provides an international framework for certifying equipment in explosive atmospheres.

- Regions Covered: Countries worldwide that accept IECEx certification, including Australia, South Africa, parts of Asia, and the Middle East.

IECEx is often considered more universal than ATEX because it is accepted outside the EU. It also provides a standardized way of testing equipment, reducing the need for multiple certifications in different countries.

Example

A mining operation in Australia may require IECEx-certified communication devices to comply with national regulations.

ATEX vs. IECEx: The Key Differences

Although ATEX and IECEx both aim to ensure safety in explosive environments, there are a few differences:

- Geographical Reach

- ATEX: Mandatory in the EU.

- IECEx: Accepted in many countries outside the EU.

- Legal vs. Voluntary

- ATEX: Legally required in Europe.

- IECEx: Voluntary but often recognized as proof of compliance in international projects.

- Documentation

- ATEX requires a Declaration of Conformity and CE marking.

- IECEx requires a Certificate of Conformity, often recognized across borders.

- Market Advantage

- Having both ATEX and IECEx makes a device more versatile and globally acceptable.

Why Do These Certifications Matter?

The importance of ATEX and IECEx certifications cannot be overstated. Here’s why they matter:

- Worker Safety – Certified devices are designed to prevent sparks, overheating, and static buildup, minimizing explosion risks.

- Regulatory Compliance – Using uncertified equipment in hazardous areas can lead to legal penalties, shutdowns, or loss of licenses.

- Operational Efficiency – Workers can safely use advanced tools like smartphones, radios, and sensors in dangerous areas without fear of causing accidents.

- Global Acceptance – Having both ATEX and IECEx certifications ensures a device can be used in multiple regions without regulatory barriers.

- Business Continuity – Safety-certified devices reduce accidents, which means fewer disruptions and higher trust from clients and partners.

The Role of Intrinsically Safe Devices

Intrinsically safe devices are those designed to prevent enough electrical or thermal energy from being released to ignite an explosive atmosphere. This is especially important for communication tools like smartphones, tablets, and radios used in hazardous industries.

Features of intrinsically safe, ATEX/IECEx-certified devices include:

- Explosion-proof housing

- Spark-free components

- Controlled surface temperatures

- Sealed ports and connectors

- Rugged design for extreme conditions

Industries That Rely on ATEX and IECEx Devices

- Oil and Gas – Exploration rigs, refineries, and storage facilities require certified devices to reduce explosion risks.

- Mining – Methane and coal dust make mines highly explosive; intrinsically safe devices are critical.

- Chemical Processing – Plants handling volatile substances need safe communication and monitoring tools.

- Logistics – Warehouses storing flammable materials must ensure safe handling.

- Food Production – Dust from grain or powdered sugar can be explosive, making certified devices necessary.

Choosing the Right Device for Hazardous Environments

When choosing devices for hazardous environments, look for:

- ATEX and IECEx certifications clearly marked.

- Ruggedness (drop-proof, water-resistant, dustproof).

- Long battery life for extended field operations.

- Connectivity features like 4G/5G, Wi-Fi, and push-to-talk.

- Customization for industry-specific needs.

- Reliable aftersales support to ensure uptime.

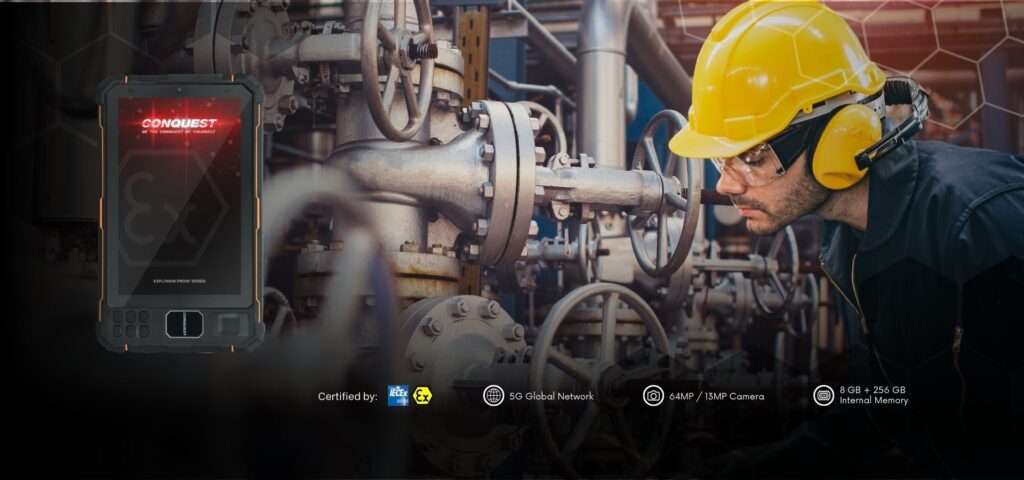

Conquest: Certified Safety and Rugged Reliability

This is where Conquest stands out. Since 2013, Conquest has specialized in rugged, intrinsically safe smartphones that are both ATEX and IECEx certified. Their devices are:

- Engineered for oil and gas, chemical, mining, logistics, and manufacturing industries.

- Designed to replace multiple devices with all-in-one performance (powerful processing, cameras, 5G connectivity, flashlight modules).

- Fully customizable, ensuring companies get solutions tailored to their needs.

- Supported by 24/7 professional assistance, guaranteeing uninterrupted operations.

Conquest smartphones are not just safe—they are powerful tools that improve efficiency, reduce costs, and enable smarter operations in hazardous environments.

Check out Top Features to Look For in Rugged Smartphones for Chemical Plants for a detailed overview of what makes a smartphone truly rugged in environments like chemical plants — from material resistance and ingress protection to battery safety and certification needs.

Conclusion

ATEX and IECEx certifications are non-negotiable standards for any device used in hazardous environments. They protect workers, ensure compliance, and keep operations running smoothly. When choosing certified devices, businesses need more than safety—they need rugged performance, customization, and dependable support.

That’s why companies across oil and gas, mining, chemicals, and logistics trust Conquest. Their ATEX and IECEx-certified smartphones combine intrinsic safety, rugged durability, and cutting-edge performance, ensuring seamless operations in the toughest environments.

Ready to upgrade your operations with certified rugged smartphones?

Discover how Conquest can keep your teams connected, safe, and efficient.

Visit Conquest to book a demo or talk to a consultant today.

FAQs

Q1. What does ATEX certification mean?

ATEX certification means a device is safe for use in explosive atmospheres within the European Union. It ensures the equipment won’t ignite gases, vapors, or dust.

Q2. What does IECEx certification mean?

IECEx certification is an international safety standard for equipment used in hazardous environments. It proves a device meets globally recognized explosion-protection requirements.

Q3. Do I need both ATEX and IECEx certifications?

Yes, if your business operates globally. ATEX is required in the EU, while IECEx provides international recognition, making devices usable in multiple regions.

Q4. Are ATEX/IECEx devices only for oil and gas industries?

No. They are also used in mining, chemicals, pharmaceuticals, food production, and logistics—anywhere flammable gases or dust may be present.

Q5. What does “intrinsically safe” mean?

It means the device is designed so that it cannot release enough electrical or thermal energy to ignite an explosive atmosphere.

Q6. Can uncertified devices be used in hazardous areas?

No. Using uncertified devices is illegal in most regions and poses serious safety risks. It can also result in fines and shutdowns.

Q7. How do I know if a device is ATEX or IECEx certified?

Check the product specifications or labeling. Certified devices clearly display their ATEX or IECEx markings, along with the relevant zone classification.

Q8. Why choose Conquest for certified devices?

Conquest offers rugged, customizable, and certified smartphones backed by 24/7 support. Their devices combine safety, performance, and reliability, making them a trusted choice for hazardous environments.

More Interesting Posts

How Conquest EX202 Enhances Operational Efficiency with Built-In Tools

Enhancing Worker Safety with Conquest EX201’s Satellite Communication

Explosion Proof Smartphones in Malaysia for Petrochemical Industry