Best Practices for Maintaining ATEX-Certified Equipment

In industries such as oil and gas, mining, chemicals, and logistics, safety is never optional—it’s a necessity. One critical aspect of ensuring safety in explosive atmospheres is the use of ATEX-certified equipment. These devices are designed and tested to prevent sparks, heat, or electrical discharge that could ignite hazardous substances.

However, simply purchasing ATEX-certified devices isn’t enough. To protect workers, stay compliant with strict regulations, and extend equipment lifespan, businesses must follow best practices for maintaining ATEX-certified equipment. This guide outlines practical steps to keep your operations safe, efficient, and fully compliant.

Understanding ATEX-Certified Equipment

Before diving into maintenance, it’s important to understand what ATEX certification means.

ATEX (short for ATmosphères EXplosibles) is a European directive that governs equipment used in explosive environments. Devices that carry ATEX certification undergo rigorous testing to ensure they will not cause ignition under normal or faulty conditions.

Key industries that rely on ATEX-certified equipment:

- Oil and Gas: Offshore rigs, refineries, pipelines.

- Chemical Manufacturing: Plants handling volatile gases and chemicals.

- Mining: Underground operations with flammable dust or gases.

- Logistics and Warehousing: Facilities managing flammable materials.

By design, ATEX-certified equipment is robust, but it still requires regular maintenance and inspections to ensure long-term reliability.

Key Maintenance Best Practices

1. Follow Manufacturer Guidelines

The very first rule in maintaining ATEX-certified equipment is to follow the manufacturer’s guidelines. Every device comes with detailed manuals that specify safe operating conditions, maintenance procedures, and repair protocols.

Ignoring these recommendations not only jeopardizes safety but can also invalidate ATEX certification. Always ensure your team is familiar with the official documentation before performing inspections or repairs.

2. Establish a Preventive Maintenance Schedule

A proactive approach is always safer—and cheaper—than a reactive one. Create a structured preventive maintenance schedule that includes:

- Daily checks: Quick visual inspections for obvious damage or abnormal operation.

- Weekly checks: Functional testing, monitoring battery health, and checking enclosures.

- Monthly checks: Detailed inspection of seals, enclosures, and grounding systems.

- Annual audits: Comprehensive review, calibration (if needed), and certification checks.

Predictive maintenance tools, such as vibration sensors or thermal imaging, can also be used to detect issues before they escalate.

3. Conduct Regular Visual & Functional Inspections

Regular inspections are essential in explosive atmospheres. Look for:

- Corrosion or wear on metallic parts.

- Seal integrity around enclosures, ensuring no dust or gas can enter.

- Loose fittings or screws that could compromise safety.

- Signs of overheating or abnormal smells.

Functional inspections ensure that devices are not only intact but also working as intended. For example, test communication equipment, load indicators, or lighting systems to confirm reliable performance.

4. Proper Cleaning & Handling Procedures

Cleaning ATEX-certified equipment isn’t as simple as wiping with a cloth. Certain cleaning agents can be hazardous in explosive zones, while abrasive methods may compromise protective coatings.

Best practices include:

- Use non-static, approved cleaning materials to prevent sparks.

- Avoid high-pressure water jets unless approved by the manufacturer.

- Ensure the device is powered off and removed from hazardous zones before cleaning.

Proper handling during transport and storage also reduces wear and tear. Always store devices in a dry, cool, and secure environment.

5. Replace Damaged or Expired Parts Promptly

Using non-certified spare parts is one of the most common—and dangerous—maintenance mistakes. Even minor substitutions can compromise ATEX compliance and increase ignition risk.

Whenever a part is damaged or reaches its service life:

- Replace it only with manufacturer-approved components.

- Record the replacement in your maintenance log.

- Train employees to recognize early signs of component failure.

6. Maintain Detailed Records & Documentation

Documentation is not only good practice—it’s often legally required. Proper record-keeping ensures compliance during audits and provides a trail of accountability.

Your records should include:

- Dates of inspections and audits.

- Details of repairs and parts replacements.

- Training records of staff handling the equipment.

- Compliance certificates and re-certifications.

In many industries, poor documentation is treated as seriously as poor maintenance.

Training and Safety Protocols

Even the best equipment can fail if users are not properly trained. Organizations must prioritize employee training for ATEX-certified equipment.

- Initial training: All staff should understand how ATEX devices work and why maintenance is critical.

- Refresher courses: Regularly update teams on safety standards and equipment upgrades.

- Emergency protocols: Workers must know how to respond if equipment malfunctions in hazardous zones.

Well-trained employees not only protect themselves but also contribute to operational efficiency and regulatory compliance.

Understanding ATEX zones is vital for industrial safety. These zones classify areas by explosion risk, helping choose the right equipment to prevent hazards.

Common Mistakes to Avoid in ATEX Maintenance

Many incidents in hazardous industries happen because of avoidable mistakes. Here are the most common pitfalls:

- Using uncertified accessories: Always use parts approved by the manufacturer.

- Skipping inspections: Delaying inspections can allow small issues to become catastrophic.

- Improper documentation: Missing logs can lead to failed audits and fines.

- Unauthorized repairs: Only certified professionals should repair ATEX devices.

Avoiding these mistakes can save money, time, and—most importantly—lives.

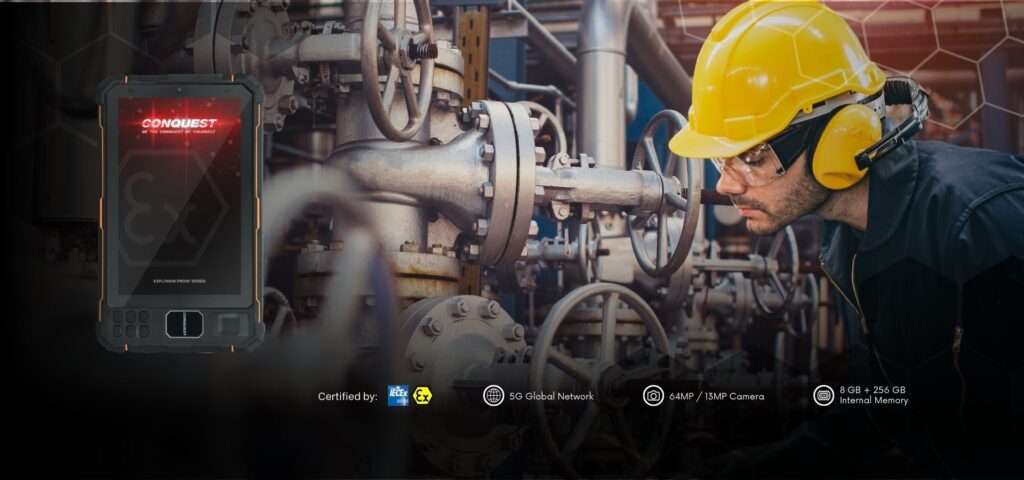

How Conquest Supports Safe Equipment Maintenance

At Conquest, we understand the challenges of maintaining ATEX-certified devices in demanding environments. That’s why we design our equipment to be as rugged, reliable, and low-maintenance as possible.

Why choose Conquest ATEX-certified devices?

- Durability: Built to withstand extreme temperatures, dust, moisture, and impact.

- Longevity: Engineered for long service life, reducing maintenance costs.

- Ease of Maintenance: Simplified designs that make inspections and cleaning faster.

- 24/7 Support: Our expert team is always available to guide you through safe equipment management.

By partnering with Conquest, you ensure that maintenance doesn’t become a burden—it becomes part of a seamless safety and productivity strategy.

Conclusion

Maintaining ATEX-certified equipment is not just about extending device life—it’s about protecting workers, staying compliant, and preventing catastrophic accidents. By following best practices for maintaining ATEX-certified equipment, businesses can ensure safety, reduce downtime, and optimize costs.

At Conquest, we specialize in providing rugged ATEX-certified smartphones and solutions designed for the world’s harshest environments. Our mission is to help businesses achieve safety and efficiency without compromise.

Book a free consultation with a Conquest expert today and discover how our ATEX-certified devices can simplify your maintenance strategy and enhance workplace safety.

Zone 1/Zone 2 Devices: Technology Trends for Risk Reduction highlight the latest innovations that enhance safety in hazardous areas, reduce risks, and ensure compliance with ATEX standards.

FAQs on ATEX Equipment Maintenance

Q1: How often should ATEX devices be inspected?

ATEX equipment should be inspected according to the manufacturer’s guidelines—typically daily visual checks, monthly functional inspections, and annual audits.

Q2: Can ATEX-certified equipment be repaired on-site?

Yes, but only by certified professionals using manufacturer-approved parts. Unauthorized repairs can void certification.

Q3: What documentation is required for audits?

You need maintenance logs, repair records, training certifications, and compliance certificates.

Q4: What happens if I use non-certified spare parts?

Using non-certified parts can compromise the explosion-proof design, void ATEX certification, and put workers at risk of ignition hazards.

Q5: Is training mandatory for maintaining ATEX equipment?

Yes. Regulations require that only trained and competent personnel handle ATEX-certified devices to ensure compliance and safety.

Q6: How do environmental conditions affect ATEX equipment maintenance?

Harsh conditions like high humidity, saltwater exposure, or dust can accelerate wear. This requires more frequent inspections and specialized cleaning.

Q7: Can ATEX-certified devices be used outside explosive environments?

Yes, but their key advantage lies in hazardous areas. Using them outside won’t harm performance, but maintenance practices should still follow ATEX guidelines.

More Interesting Posts

How Conquest EX202 Enhances Operational Efficiency with Built-In Tools

Enhancing Worker Safety with Conquest EX201’s Satellite Communication

Explosion Proof Smartphones in Malaysia for Petrochemical Industry