Choosing the Right Intrinsically Safe Device for Logistics and Manufacturing

In logistics and manufacturing, efficiency and safety must work hand in hand. Whether it’s a bustling warehouse, a chemical processing plant, or a global supply chain hub, hazardous environments require technologies that protect workers while maintaining operational productivity. That’s where intrinsically safe devices come in.

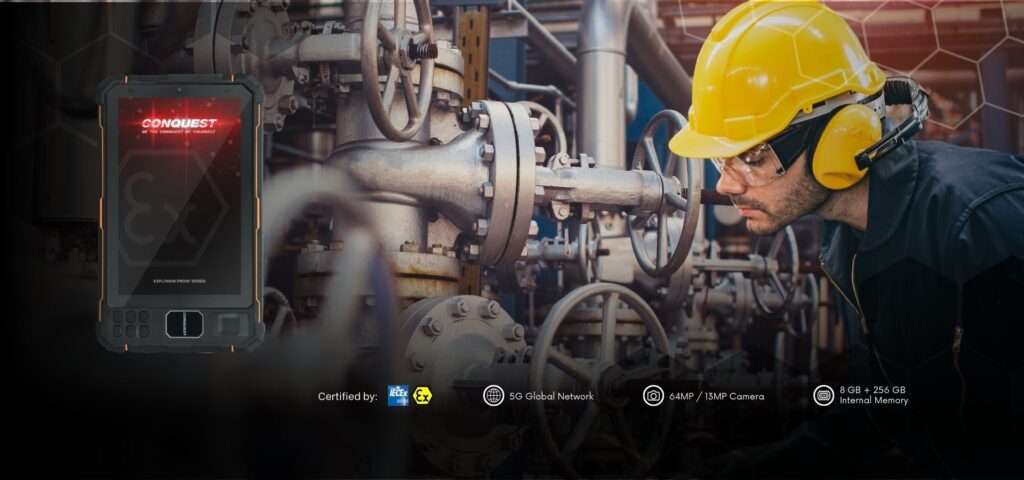

These specialized smartphones, sensors, and tablets are designed to operate safely in explosive or flammable atmospheres. They prevent sparks, heat, or electrical energy from causing accidents, ensuring compliance with international standards such as ATEX, IECEx, and NEC.

In this guide, we’ll walk you through everything you need to know about choosing the right intrinsically safe device for logistics and manufacturing—from compliance and classifications to real-world applications and industry-leading solutions from Conquest EX.

What Are Intrinsically Safe Devices?

Intrinsically safe devices are electronic tools engineered to operate in hazardous locations without igniting flammable gases, vapors, or dust. Unlike standard rugged devices, they incorporate energy-limiting circuits and protective components to minimize risks.

Key Difference From Explosion-Proof Devices

- Intrinsically Safe (IS): Limits energy at the source, preventing sparks or heat.

- Explosion-Proof: Contains explosions within the device casing.

For industries like logistics and manufacturing—where safety, portability, and compliance are essential—intrinsically safe devices are the gold standard.

Why Logistics and Manufacturing Need Intrinsically Safe Devices

-

Safety Compliance

Regulatory frameworks demand strict adherence to safety standards. Using uncertified devices in hazardous zones can result in heavy fines, legal liabilities, or worse—catastrophic accidents. Certifications such as ATEX certifications, IECEx, CSA, and NEC ensure compliance and peace of mind.

-

Operational Continuity

Unexpected downtime is costly. Intrinsically safe devices minimize risks of accidents that could halt production, helping logistics centers and manufacturing plants maintain uptime.

-

Worker Protection

Frontline workers rely on mobile technology for communication, scanning, monitoring, and reporting. Safe devices reduce the risk of injury, protecting both employees and company reputation.

-

Industry Case Example

Consider a chemical manufacturing plant handling solvents. Without IS-certified smartphones, a single spark during data entry could endanger lives. By using Conquest EX-certified devices, the plant ensures uninterrupted safety and compliance.

Key Factors When Choosing an Intrinsically Safe Device

When selecting a device, decision-makers should evaluate both compliance and operational needs.

-

Hazardous Area Classification

- Zone 0 / Division 1: Areas with continuous exposure to flammable materials.

- Zone 1 / Division 2: Intermittent exposure.

- Zone 2: Rare exposure.

Choose devices certified for the specific zone your facility operates in.

-

Device Type

- Smartphones for communication and apps.

- Tablets for data entry and inspections.

- Sensors for monitoring temperature, pressure, or vibration.

- Radios for instant push-to-talk communication.

-

Certifications to Look For

- ATEX (Europe)

- IECEx (International)

- UL, CSA (North America)

-

Durability & Ruggedness

Check for IP ratings (dust/water resistance), MIL-STD certifications (shock/drop resistance), and wide operating temperature ranges.

-

Connectivity & Integration

Modern logistics and manufacturing demand devices that support:

- 5G & Wi-Fi for fast data transfer.

- Bluetooth/IoT compatibility for sensor integration.

- Enterprise software for real-time tracking.

-

Battery & Power Management

Look for energy-limited batteries with hot-swappable options. Long shifts in warehouses or factories demand devices that last 12+ hours without compromising safety.

Intrinsically Safe Devices for Logistics Operations

-

Real-Time Tracking & Asset Management

IS smartphones and tablets allow workers to track shipments, update inventory, and verify deliveries—even in ATEX Zone 1 environments.

-

Barcode Scanning & Warehouse Automation

Many IS devices integrate barcode scanners, enabling faster workflows without risking ignition.

-

Hands-Free Communication in Hazardous Zones

Push-to-talk and voice-activated controls allow workers to stay connected while handling flammable goods safely.

Intrinsically Safe Devices for Manufacturing Environments

-

Process Monitoring & Control

IS sensors track environmental factors like temperature and gas levels to ensure operational safety.

-

Quality Assurance & Compliance Checks

IS tablets streamline inspections, audits, and compliance reporting.

-

Data Capture & Predictive Maintenance

By integrating with IoT platforms, IS devices support predictive maintenance, reducing breakdowns and ensuring continuous output.

Understanding ATEX zones is vital for industrial safety. These zones classify areas by explosion risk, helping choose the right equipment to prevent hazards.

Conquest EX Case Study – Smart Solutions for Hazardous Workflows

When it comes to choosing the right intrinsically safe device for logistics and manufacturing, Conquest EX has established itself as a trusted global partner. Unlike generic rugged device manufacturers, Conquest EX focuses exclusively on creating mobile technologies that meet the highest safety standards without compromising performance.

-

Rugged Design Tailored for Industry

Conquest EX devices are built to survive the toughest working conditions. From high-temperature foundries and chemical plants to dusty warehouses and outdoor logistics hubs, these devices deliver consistent performance where ordinary consumer devices fail. Their construction is guided by MIL-STD-810H durability standards, ensuring resistance to drops, vibration, moisture, and extreme weather. This rugged reliability allows frontline teams to stay connected and productive, regardless of the environment.

-

Certifications That Guarantee Compliance

Safety isn’t optional—it’s a requirement. Every Conquest EX device undergoes rigorous testing and carries ATEX and IECEx certifications, ensuring it can safely operate in hazardous zones (Zone 1/21 and Zone 2/22). This means logistics and manufacturing companies can deploy them across different geographies with full confidence that they meet international compliance standards.

By aligning with global certification systems, Conquest EX devices reduce the risk of non-compliance fines and help organizations demonstrate safety leadership in industries where regulations are strict and audits frequent.

-

Real-World Case Studies

- China Railway:

For one of the largest transportation networks in the world, ensuring worker safety in confined and hazardous spaces is critical. Conquest EX devices provided reliable intrinsically safe communication solutions for engineers and field staff, enabling real-time reporting and coordination without compromising safety. - Bluestar & ChemChina:

In chemical manufacturing plants, even a small electrical spark could result in catastrophic explosions. Bluestar and ChemChina deployed Conquest EX smartphones and tablets to their teams, integrating them with process monitoring systems. This allowed workers to capture inspection data, communicate instantly, and follow safety protocols seamlessly—all while staying compliant with ATEX/IECEx requirements. - Manufacturing Clients in Southeast Asia:

Several large-scale factories have turned to Conquest EX for intrinsically safe IoT integration. Devices were deployed as part of predictive maintenance programs, where they monitor machine health and flag anomalies before breakdowns occur. The result: reduced downtime, lower maintenance costs, and improved worker safety.

-

Differentiators That Matter

Conquest EX doesn’t just make devices safe—it makes them smart, adaptable, and future-ready.

- 5G-Ready: Future-proof connectivity ensures that as logistics and manufacturing operations adopt Industry 4.0 technologies, Conquest EX devices remain compatible and competitive.

- Customizable Solutions: Unlike many one-size-fits-all providers, Conquest EX works with clients to develop custom configurations, software integrations, and accessories tailored to specific workflows.

- Enterprise Integration: Devices seamlessly integrate with popular ERP, WMS, and MES systems, making them easy to adopt without disrupting existing digital infrastructure.

- Global Support: With 24/7 technical support and service centers across multiple regions, Conquest EX ensures organizations get the help they need, whenever they need it.

Final Thoughts

For logistics and manufacturing, choosing the right intrinsically safe device is not just a compliance necessity—it’s a business-critical decision. The right solution ensures worker safety, minimizes downtime, and future-proofs operations.

Conquest EX offers a trusted portfolio of devices that combine rugged design, global certifications, and innovative features—making them ideal for organizations navigating hazardous workflows.

Ready to enhance your logistics and manufacturing operations with ATEX & IECEx certified devices? Contact Conquest EX today to explore tailored intrinsically safe solutions that redefine safety and performance.

Zone 1/Zone 2 Devices: Technology Trends for Risk Reduction highlight the latest innovations that enhance safety in hazardous areas, reduce risks, and ensure compliance with ATEX standards.

FAQs on Intrinsically Safe Devices

Q1: What’s the difference between intrinsically safe and explosion-proof devices?

IS devices prevent sparks at the source, while explosion-proof devices contain explosions inside heavy enclosures.

Q2: Can regular devices be used with protective cases?

No. Cases may protect physically, but they don’t certify the electronics for hazardous use.

Q3: How often do devices need re-certification?

Certifications remain valid unless modifications are made, but periodic audits may be required by local authorities.

Q4: Are IS devices future-ready (IoT, 5G, AI)?

Yes. Leading providers like Conquest EX integrate 5G, IoT compatibility, and advanced features.

Q5: Do intrinsically safe devices perform as well as standard rugged devices?

Modern IS devices deliver comparable performance—offering high-resolution displays, fast processors, 5G connectivity, and rugged durability—while meeting strict safety standards.

Q6: What industries benefit most from intrinsically safe devices?

Beyond logistics and manufacturing, IS devices are essential in oil & gas, chemical processing, pharmaceuticals, mining, utilities, and transportation—anywhere flammable materials or explosive atmospheres exist.

More Interesting Posts

How Conquest EX202 Enhances Operational Efficiency with Built-In Tools

Enhancing Worker Safety with Conquest EX201’s Satellite Communication

Explosion Proof Smartphones in Malaysia for Petrochemical Industry