Environmental Impact of Industrial Mobile Devices: What Companies Should Know

Industrial mobile devices have become the backbone of modern operations across oil and gas, logistics, manufacturing, and utilities. These devices enable real-time communication, enhance safety, and streamline workflows in some of the harshest environments. But while they boost productivity, they also come with an environmental footprint that companies can’t afford to ignore.

The environmental impact of industrial mobile devices extends from their manufacturing process and energy consumption to disposal and recycling challenges. Understanding this impact is crucial for companies that are striving to balance innovation with sustainability. Businesses now face the question: how can we equip our teams with high-performance technology without compromising our environmental responsibilities?

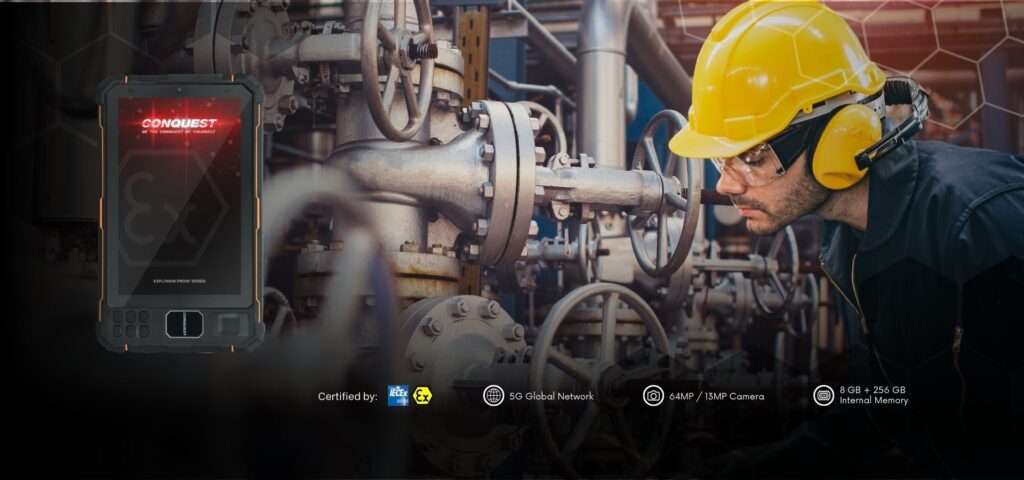

Let’s explore how industrial mobile devices affect the planet, what companies should know, and how choosing the right partner—like Conquest—can make all the difference.

1. The Lifecycle of an Industrial Mobile Device

Every industrial mobile device goes through three main stages: production, operation, and end-of-life. Each phase leaves an environmental footprint.

a) Manufacturing and Material Use

The production phase is energy-intensive. It involves mining and processing raw materials such as lithium, cobalt, and rare earth metals—key components of batteries and electronic circuits. Mining often leads to deforestation, water pollution, and high carbon emissions.

However, manufacturers that prioritize responsible sourcing and energy-efficient production can significantly reduce environmental harm. Choosing suppliers with verified certifications and ethical mining practices ensures that every device contributes less to ecological degradation.

b) Operational Energy Use

During its operational life, a mobile device consumes electricity—mostly through charging cycles. While each device may use a small amount of energy daily, large industrial fleets multiply that figure quickly. The key lies in battery efficiency and energy management systems that extend battery life and reduce the need for frequent charging.

Devices like Conquest’s rugged smartphones, for example, are engineered for optimized energy performance—delivering long-lasting power that minimizes environmental strain while maximizing uptime.

c) Disposal and E-Waste Management

End-of-life disposal remains one of the most pressing concerns. E-waste contains toxic materials that can contaminate soil and water. Companies must ensure proper recycling processes that reclaim valuable materials and safely dispose of hazardous components. Many leading technology providers now offer take-back or recycling programs, helping enterprises meet sustainability goals.

2. The Hidden Carbon Footprint and the Role of IoT Integration: How Smart Devices Are Revolutionizing Hazardous Site Monitoring

Industrial mobile devices may appear small, but together they contribute to a significant carbon footprint. From manufacturing components powered by fossil fuels to the logistics involved in global distribution, each stage adds to cumulative emissions. Reducing this footprint requires smarter technology design, improved efficiency, and data-driven management—areas where modern IoT integration plays a transformative role.

IoT Integration: How Smart Devices Are Revolutionizing Hazardous Site Monitoring is a key factor in minimizing the environmental impact of industrial operations. By connecting rugged, ATEX-certified devices to intelligent monitoring systems, companies gain real-time visibility into energy use, equipment health, and environmental conditions. This allows for predictive maintenance, optimized energy consumption, and reduced equipment downtime—all of which help lower the overall carbon output.

Through IoT-enabled insights, organizations can make informed decisions about when to repair, replace, or recycle devices, avoiding unnecessary production and waste. The result is a more sustainable, efficient, and safer work environment—particularly in industries like oil and gas, logistics, and manufacturing, where operational efficiency directly impacts environmental performance.

Selecting rugged devices built for durability and equipped for IoT connectivity, such as those offered by Conquest, further enhances this sustainability advantage. A device that lasts longer, consumes less power, and contributes data to smarter environmental strategies becomes more than a tool—it becomes a driver of corporate sustainability.

3. Extending Device Lifespan: A Simple Way to Go Green

Longevity is one of the most effective ways to minimize environmental harm. Devices designed for durability not only reduce costs but also limit waste generation.

Rugged devices, such as those built by Conquest, can withstand extreme heat, moisture, dust, and shock. They are less likely to fail under pressure, meaning fewer replacements and repairs. This not only saves operational costs but also prevents unnecessary electronic waste.

Additionally, software updates and modular components allow companies to upgrade features without replacing entire devices—further reducing environmental impact.

4. Sustainable Manufacturing Practices

Forward-thinking manufacturers are reimagining how devices are built. These practices include:

- Recycled materials: Using recycled plastics and metals in casings.

- Reduced packaging: Switching to biodegradable or recyclable packaging.

- Cleaner production lines: Powering factories with renewable energy sources.

- Efficient logistics: Shorter supply chains and smarter shipping reduce emissions.

Conquest’s commitment to quality assurance and continuous improvement aligns with these principles. Their ATEX and IECEx-certified smartphones not only deliver operational safety but are also crafted for long-term use, promoting environmental responsibility.

5. Responsible Disposal and Recycling

Proper e-waste management can reclaim valuable materials like gold, copper, and lithium while preventing toxic leakage. Companies can implement structured recycling programs or partner with certified recyclers.

Some businesses go further by refurbishing old devices for secondary use—such as training or non-critical operations—extending the lifecycle and reducing waste output.

Conquest supports responsible disposal practices by ensuring each product adheres to international environmental standards, reducing hazardous waste at the end of its life cycle.

6. The Role of Regulations, Certifications, and Best Practices for Maintaining ATEX-Certified Equipment

Sustainability and safety are not optional—they are business essentials. Around the world, industries are under growing pressure to meet strict standards that protect both people and the planet. Understanding key regulations and implementing Best Practices for Maintaining ATEX-Certified Equipment ensures your organization stays compliant while enhancing the longevity and eco-efficiency of its industrial devices.

Key regulatory frameworks include:

- WEEE Directive (EU) – Governs the responsible disposal and recycling of electronic equipment.

- RoHS Compliance – Limits the use of hazardous substances in electrical and electronic products.

- ISO 14001 Certification – Encourages companies to implement comprehensive environmental management systems.

- ATEX and IECEx Certifications – Guarantee safety in explosive or hazardous environments through rigorous product testing and design controls.

But certification alone isn’t enough. Companies must adopt best practices for maintaining ATEX-certified equipment to ensure these devices perform safely and efficiently over time. This includes routine inspections, proper cleaning with approved materials, software updates to maintain compliance, and using only certified accessories or replacement parts. These practices reduce premature failures, extend device lifespan, and minimize environmental waste—all while maintaining operational safety standards.

By following these guidelines and choosing certified partners like Conquest, businesses can meet their sustainability goals without compromising safety or performance. Every Conquest device reflects this dual commitment—offering dependable operation in hazardous environments while supporting a cleaner, more responsible industrial future.

7. How Companies Can Reduce Their Device-Related Footprint

There are practical steps businesses can take right now:

- Invest in rugged, long-life devices – Reduces frequent replacement cycles.

- Adopt energy-efficient charging – Use smart charging systems to minimize waste.

- Set up recycling partnerships – Ensure proper end-of-life management.

- Choose suppliers with transparent sourcing – Support responsible manufacturing.

- Train employees – Encourage proper device maintenance and recycling habits.

By embedding sustainability into their technology strategy, companies can achieve both operational efficiency and environmental stewardship.

8. Conquest’s Approach to Eco-Conscious Innovation

Conquest’s vision of technology goes beyond performance—it’s about safety, durability, and responsibility. Every Conquest device is designed for rugged performance and extended lifespan, reducing waste and environmental strain.

Their bespoke innovations allow companies to tailor devices to their exact operational needs, eliminating the need for multiple tools and reducing electronic clutter. Combined with ATEX and IECEx certifications, Conquest smartphones offer peace of mind, ensuring both safety and sustainability in hazardous environments.

By choosing Conquest, companies align with a partner committed to both technological excellence and environmental care.

9. The Future of Green Industrial Technology

The future of industrial mobility lies in smart, durable, and sustainable technology. Advancements like modular components, solar-powered charging systems, and biodegradable materials are reshaping how devices are made and used.

Businesses that embrace eco-conscious innovation today will be tomorrow’s leaders in both performance and responsibility. As environmental expectations rise, sustainability becomes not just a compliance requirement but a competitive advantage.

Conclusion

The environmental impact of industrial mobile devices is undeniable—but manageable. With responsible sourcing, efficient operation, and proper disposal, businesses can minimize their ecological footprint while maximizing productivity.

Conquest exemplifies this balance. Their rugged, ATEX and IECEx-certified smartphones empower industries to communicate safely, operate efficiently, and advance sustainably. For companies aiming to enhance performance without compromising environmental integrity, Conquest stands as the trusted partner of choice.

Ready to elevate your industrial operations while reducing your environmental impact?

Explore Conquest’s range of rugged, safety-certified smartphones engineered for sustainable performance in challenging environments.

FAQs

- What is the environmental impact of industrial mobile devices?

They contribute to carbon emissions, resource depletion, and e-waste generation across manufacturing, usage, and disposal stages. - How can companies reduce e-waste from mobile devices?

By investing in durable, long-lasting devices and participating in certified recycling programs. - Are rugged devices more eco-friendly?

Yes. Rugged devices last longer, reducing the need for frequent replacements and minimizing e-waste. - What certifications should eco-conscious companies look for?

Look for ATEX, IECEx, RoHS, and ISO 14001 certifications for safety and environmental compliance. - How does battery efficiency affect sustainability?

Efficient batteries reduce energy consumption and extend device lifespan, lowering overall environmental impact. - Can recycling old devices recover valuable materials?

Absolutely. Recycling reclaims metals like gold and copper, reducing the need for new mining. - How does Conquest support sustainability?

Conquest designs long-lasting, ATEX-certified devices built to reduce waste, enhance safety, and promote eco-efficient operations. - Why is device longevity crucial for green goals?

Long-lasting devices mean fewer replacements, less manufacturing demand, and lower carbon emissions.

More Interesting Posts

How Conquest EX202 Enhances Operational Efficiency with Built-In Tools

Enhancing Worker Safety with Conquest EX201’s Satellite Communication

Explosion Proof Smartphones in Malaysia for Petrochemical Industry