Explosion Proof Cameras: The Silent Guardians of Hazardous Environments

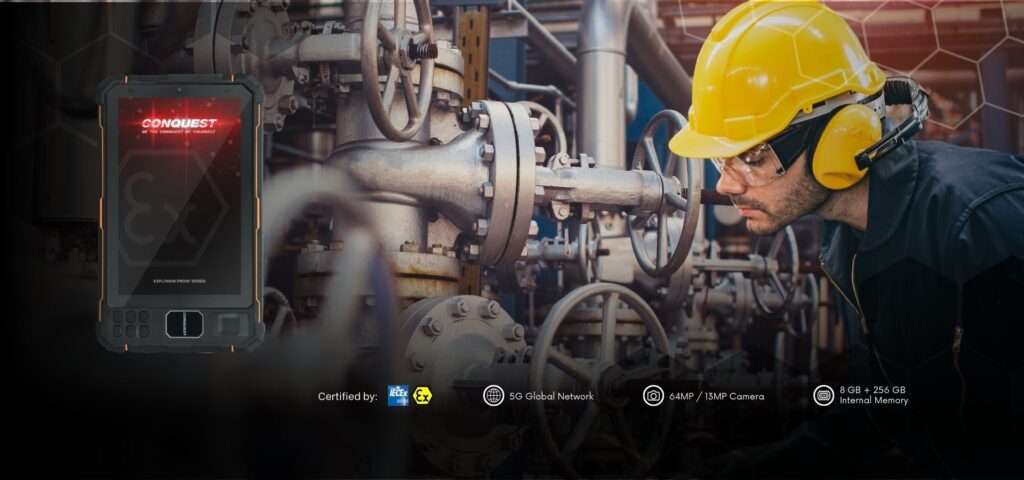

In volatile environments, one spark is all it takes. That’s why explosion proof cameras are essential in high-risk industries like oil & gas, chemical plants, and manufacturing. These specialized cameras are designed to ensure safety by preventing sparks, heat, or electrical components from igniting dangerous substances. For industries like these, it’s also essential to use intrinsically safe smartphones like those found at Conquest Explosion Proof, which are designed to enhance safety and functionality in hazardous areas.

An explosion proof camera not only provides crucial surveillance but also safeguards personnel, processes, and equipment from catastrophic accidents. By withstanding extreme conditions, these cameras help monitor areas that are otherwise too dangerous for human presence. In this article, we’ll explore how explosion proof cameras work, where they are used, and how they can enhance safety in hazardous environments. Whether it’s for industrial inspections, real-time monitoring, or remote surveillance, understanding the role of these devices can be the key to maintaining safety and compliance in critical sectors. Let’s dive in!

What Is an Explosion Proof Camera?

An explosion proof camera is a specialized surveillance device engineered to operate safely in hazardous environments where flammable gases, vapors, or dust may be present. These cameras are built to contain any sparks or heat generated by their internal components, preventing them from igniting explosive substances in the surrounding environment. For the safest communication in such areas, intrinsically safe mobile phones and ATEX phones like those from Conquest are also crucial.

Certification Standards:

To ensure the highest safety standards, explosion proof cameras are certified under strict international regulations such as ATEX (from Europe) and IECEx (from international standards). These certifications guarantee that the cameras meet the safety requirements for use in explosive atmospheres. ATEX certification focuses on equipment safety for use in explosive atmospheres within the EU, while IECEx ensures international compliance for such equipment.

Common Misconceptions:

Many people confuse “explosion proof” with “explosion protected.” The term explosion proof indicates that the camera can withstand an internal explosion without igniting the external environment, while explosion protected refers to cameras that can only prevent sparks and flames from escaping. It’s essential to understand the difference when choosing an appropriate camera for hazardous settings.

Design Elements:

An explosion proof camera typically features:

- Durable housing: Made from materials like stainless steel or heavy-duty aluminum, which can withstand extreme conditions.

- Spark containment: The sealed casing ensures that sparks or heat generated inside the camera are safely contained.

- Heat control: Special thermal management systems are in place to regulate internal temperature, ensuring safe operation without overheating.

These design elements make explosion proof cameras vital for preventing accidents in dangerous, volatile areas. If your work involves hazardous environments, using a thermal imaging smartphone will complement the camera systems by allowing you to detect temperature changes in real-time.

How Do Explosion Proof Cameras Work?

Explosion proof cameras work by employing a variety of safety mechanisms that allow them to operate safely in hazardous environments. The primary purpose is to prevent any internal heat, spark, or electrical discharge from igniting flammable gases or dust.

Preventive Design:

- Sparks Containment: The sealed, robust casing of an explosion proof camera keeps sparks or heat generated inside from escaping.

- Heat Regulation: Advanced thermal management systems ensure the camera doesn’t overheat, which could potentially cause a spark or ignition.

- Internal Safety Mechanisms: Explosion proof cameras feature secure wiring and components that are shielded to reduce the risk of malfunction. This includes the use of flameproof enclosures to prevent any internal combustion from affecting the surroundings.

These cameras are particularly useful in hazardous zones like Zone 1 (high risk) and Zone 2 (lower risk but still hazardous), ensuring constant monitoring without compromising safety.

Types of Explosion Proof Cameras

There are various types of explosion proof cameras to suit different industrial applications. Here’s a breakdown of the main types:

- Bullet Cameras:

- Compact and lightweight, these cameras are designed for specific areas, such as entrances or areas requiring focused surveillance.

- They are ideal for surveillance in confined spaces or targeted locations.

- Compact and lightweight, these cameras are designed for specific areas, such as entrances or areas requiring focused surveillance.

- Dome Cameras:

- With their vandal-resistant and weatherproof design, dome cameras provide a wide-angle view and are suitable for outdoor use.

- These cameras are perfect for larger spaces, providing all-around coverage for general surveillance.

- With their vandal-resistant and weatherproof design, dome cameras provide a wide-angle view and are suitable for outdoor use.

- PTZ (Pan-Tilt-Zoom) Cameras:

- PTZ cameras can be controlled remotely, offering a 360-degree field of view with zoom capabilities.

- They are ideal for covering large areas, such as production floors or offshore platforms, where operators need to adjust the camera’s position or zoom for detailed surveillance.

- PTZ cameras can be controlled remotely, offering a 360-degree field of view with zoom capabilities.

- Corrosion-Proof Cameras:

- These cameras are specifically designed to withstand corrosive substances, such as chemicals, seawater, or extreme temperatures.

- Essential in environments like chemical plants or offshore oil rigs, corrosion-proof cameras provide reliable monitoring in harsh conditions.

- These cameras are specifically designed to withstand corrosive substances, such as chemicals, seawater, or extreme temperatures.

Each camera type serves different needs, making it easier to select the right solution for a given environment, whether it’s focused surveillance or broad-area monitoring.

Industry Applications

The use of explosion proof cameras spans across various high-risk industries. Here are some of the most common sectors where these cameras are essential:

- Oil & Gas:

- Used on offshore rigs, onshore drilling sites, and refineries for continuous monitoring of volatile environments.

- Provides real-time video to prevent accidents and assist with regulatory compliance.

- Used on offshore rigs, onshore drilling sites, and refineries for continuous monitoring of volatile environments.

- Chemical & Pharmaceutical:

- Monitors chemical processing plants to prevent accidents from volatile chemicals.

- Ensures safe operation of machinery and storage facilities.

- Monitors chemical processing plants to prevent accidents from volatile chemicals.

- Biogas & Waste Management:

- Helps monitor biogas plants, ensuring that hazardous gases do not escape.

- Used to monitor waste processing and prevent the buildup of harmful emissions.

- Helps monitor biogas plants, ensuring that hazardous gases do not escape.

- Manufacturing & Engineering:

- Ensures that industrial processes run smoothly and efficiently.

- Explosion proof cameras can track production lines and prevent downtime.

- Ensures that industrial processes run smoothly and efficiently.

- Marine & Subsea:

- Ideal for monitoring submerged platforms or ships at sea where corrosion is a constant issue.

- Helps in monitoring remote areas where human presence is impossible or unsafe.

- Ideal for monitoring submerged platforms or ships at sea where corrosion is a constant issue.

Each of these industries benefits greatly from the use of explosion proof cameras, as they can help ensure safety, regulatory compliance, and operational efficiency.

Key Benefits of Explosion Proof Cameras

The advantages of using explosion proof cameras are numerous and significant, especially in industries that prioritize safety and operational efficiency.

- Real-Time Monitoring: Provides continuous surveillance of hazardous zones, offering live feedback and alerting operators to potential risks before they escalate.

- Reduced Risk to Personnel: By allowing remote monitoring, explosion proof cameras minimize the need for human presence in dangerous environments.

- Compliance and Data Logging: Assists in maintaining regulatory compliance by automatically logging data for audits and inspections.

- Enhanced Operational Efficiency: Continuous monitoring helps prevent downtime, optimize industrial processes, and improve overall productivity.

Integrating with Smart Devices in Explosive Zones

To further enhance safety, explosion proof cameras can be integrated with rugged, ATEX-certified smartphones like the Conquest EX201. This seamless connectivity allows for efficient control and monitoring of camera systems directly from a mobile device, ensuring workers can access live data and make critical decisions in real time.

This integration helps create a unified safety ecosystem in hazardous environments, combining cutting-edge explosion proof cameras with mobile technology for ultimate performance and reliability.

What to Look for When Choosing an Explosion Proof Camera

Choosing the right explosion proof camera involves considering several factors to ensure maximum safety and performance. Here’s what to look for:

- Certification (ATEX/IECEx): Make sure the camera is certified for use in explosive environments.

- Camera Resolution & Optical Zoom: Higher resolution and optical zoom capabilities ensure detailed monitoring and better image quality.

- Remote Operability: Choose a camera that can be controlled remotely, allowing you to adjust angles and zoom remotely.

- Material Build (316L Stainless Steel vs. 304): 316L stainless steel is corrosion-resistant and ideal for harsher environments than 304 steel.

- Anti-Corrosion Coating: Look for cameras with coatings that protect against corrosion, especially for chemical and marine industries.

- Compatibility with Control Systems: Ensure the camera is compatible with your existing control and monitoring systems for easy integration.

The Future: Smart Surveillance in Hazardous Areas

As technology advances, explosion proof cameras are becoming smarter, thanks to the integration of IoT (Internet of Things) and AI. These innovations allow for:

- Remote Diagnostics: Camera systems can now provide real-time diagnostics, helping to predict failures before they occur.

- Predictive Maintenance: By analyzing data, AI can alert operators to wear and tear, reducing downtime.

- Real-Time Alerts: AI-powered cameras can send instant alerts for unusual activity, improving response times in critical situations.

The future of explosion proof cameras is closely tied to innovations in artificial intelligence and machine learning, allowing for predictive analytics that can save time and prevent potential failures before they happen.

Final Thoughts

In critical sectors like oil & gas, chemicals, and pharmaceuticals, the role of explosion proof cameras cannot be overstated. These cameras not only protect lives but also ensure operational efficiency and regulatory compliance. For businesses operating in hazardous environments, integrating these devices is essential for maintaining safety and minimizing risk.

Ready to elevate your industrial safety game?

Conquest’s ATEX & IECEx-certified smartphones are engineered to work seamlessly in hazardous environments—pair them with your explosion proof camera systems for next-level communication, control, and compliance.

Frequently Asked Questions

Explosion proof cameras are designed to withstand hazardous conditions where flammable gases, vapors, or dust are present. They have special housing, spark containment, and heat control features that allow them to operate safely in environments where regular cameras would pose a safety risk.

Industries like oil & gas, chemical plants, pharmaceuticals, waste management, and marine environments require explosion proof cameras to ensure safety and compliance in volatile environments.

Yes, explosion proof cameras are often used outdoors, particularly in industries like marine and oil & gas, where they are exposed to harsh environmental conditions, including high humidity, extreme temperatures, and corrosive substances.

Explosion proof cameras help maintain compliance by offering surveillance footage that can be used for audits and inspections. They also provide real-time data that helps ensure safety protocols are followed.

Look for certifications such as ATEX (for Europe) and IECEx (international) to ensure the camera meets the necessary safety standards for use in explosive environments.

Many explosion proof cameras offer remote monitoring capabilities, allowing operators to view live footage and control camera settings from a secure location, often via smartphones or computer systems.

The cost of explosion proof cameras varies depending on the model, features, and certifications. On average, prices can range from a few hundred to several thousand dollars.

While explosion proof cameras are designed to be durable and long-lasting, regular maintenance is still required, such as cleaning the lens, checking the camera’s connections, and ensuring the housing remains intact.

More Interesting Posts

Enhancing Worker Safety with Conquest EX201’s Satellite Communication

Explosion Proof Smartphones in Malaysia for Petrochemical Industry