Hazardous Environment Regulations: Compliance Tips for Mobile Technology

Hazardous Environment Regulations: Compliance Tips for Mobile Technology

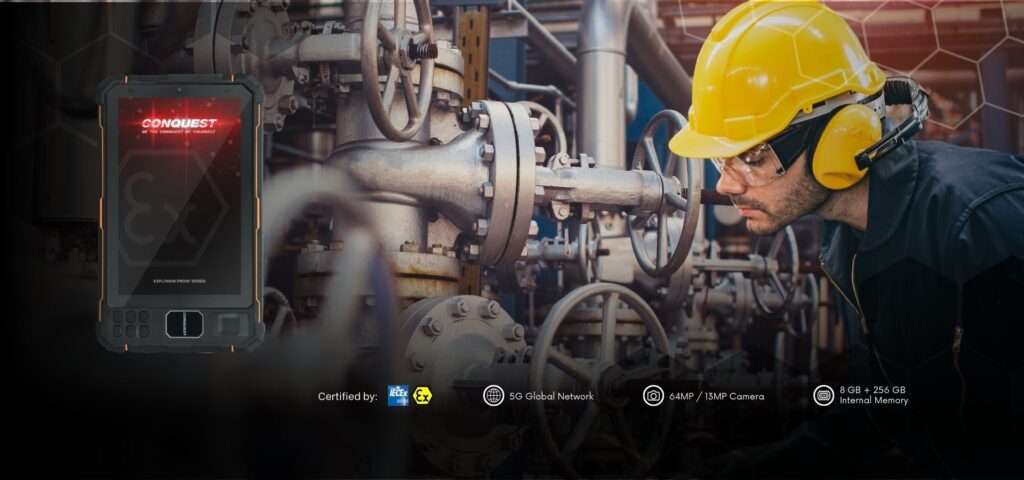

In industries such as oil and gas, chemical processing, mining, utilities, and logistics, safety and compliance are non-negotiable. Workers operate daily in environments where a single spark, device failure, or lapse in regulation can lead to catastrophic consequences. At the same time, frontline teams increasingly rely on mobile technology—smartphones, tablets, and connected devices—to communicate, monitor, and maintain productivity in real time.

This raises a critical question: how can organizations embrace digital transformation while staying compliant with hazardous environment regulations?

This guide explores the global regulatory landscape, practical compliance tips, common mistakes to avoid, and the future of safe mobile deployments.

Understanding Hazardous Environment Regulations

Hazardous areas are defined as workplaces where flammable gases, vapors, or combustible dusts may be present. Regulations and certification frameworks exist worldwide to prevent equipment from becoming an ignition source.

Key Standards and Certifications

- ATEX (Atmosphères Explosibles) – European directive ensuring devices are safe for use in explosive atmospheres.

- IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres) – International framework recognized across multiple regions.

- NEC/CEC (U.S. and Canada) – National Electrical Code (NEC) and Canadian Electrical Code (CEC) define Class, Division, and Zone hazardous locations.

- OSHA (Occupational Safety and Health Administration) – U.S. regulatory body that enforces compliance with safety practices.

Why Compliance Matters

Non-compliance exposes companies to:

- Safety risks – worker injuries, fires, explosions.

- Legal liabilities – fines, shutdowns, loss of operating licenses.

- Reputation damage – loss of trust among clients, investors, and regulators.

Compliance isn’t just about checking boxes—it’s about protecting lives and ensuring operational continuity.

The Role of Mobile Technology in Hazardous Environments

Mobile devices have revolutionized industrial operations. In hazardous industries, they serve as digital lifelines for frontline teams.

Practical Use Cases

- Real-time communication: Push-to-talk, messaging, and video calls enable faster responses.

- Asset inspections and reporting: Mobile apps streamline compliance reporting and defect detection.

- Remote monitoring: Connected devices support predictive maintenance and sensor integration.

- Worker safety apps: Digital permits-to-work, geofencing, and SOS alerts increase protection.

Why Certification Matters

A consumer smartphone may function in an office, but in a refinery or offshore platform, it poses a serious ignition risk. Devices must be:

- Ruggedized for extreme environments (shock, vibration, water, dust).

- Certified (ATEX/IECEx/NEC) to ensure they meet explosion-proof standards.

- Integrated with mobile device management (MDM) for security and compliance control.

Compliance Tips for Deploying Mobile Devices

1. Choose Certified Devices and Accessories

Select ATEX/IECEx-certified smartphones and tablets. Avoid uncertified accessories such as chargers or mounts, which can compromise compliance.

2. Match Devices to Zone Classifications

Different environments have different levels of risk:

- Class I, Division 1 (Zone 0/1): Continuous or frequent exposure to flammable substances.

- Class I, Division 2 (Zone 2): Exposure occurs only under abnormal conditions.

Always validate classification with a certified safety engineer before deployment.

3. Implement Mobile Device Management (MDM)

Compliance extends beyond hardware. An MDM platform allows organizations to:

- Control which apps are installed.

- Push software updates remotely.

- Enforce encryption and password policies.

- Track devices for audits.

4. Train Employees on Safe Usage

Even with certified devices, unsafe practices can compromise safety. Training should cover:

- Approved charging practices.

- Device handling and inspection.

- Reporting signs of device wear or malfunction.

- Safe app usage aligned with corporate security standards.

5. Establish Maintenance and Audit Programs

- Perform monthly inspections for case seals and hardware integrity.

- Maintain digital logs for device service history.

- Conduct annual audits and recertification with third-party assessors.

Compliance is not a one-time action—it’s a continuous process.

Common Compliance Mistakes to Avoid

Even the most safety-conscious organizations can unintentionally compromise compliance when deploying mobile devices in hazardous environments. These mistakes not only increase risk but can also lead to fines, shutdowns, or serious safety incidents. Here are the most common pitfalls to watch out for—and how to prevent them.

1. Using Uncertified Devices or Accessories

The most frequent and dangerous mistake is relying on non-certified smartphones, tablets, chargers, or mounts. A consumer-grade device may seem cost-effective, but without ATEX/IECEx certification, it poses a severe ignition risk. Even something as small as a spark from an uncertified charger can trigger an explosion in a volatile environment.

Prevention Tip: Always verify that both devices and accessories carry the proper certifications for your hazardous zone classification (e.g., Class I Div 2 or Zone 2).

2. Overlooking Zone Classification Requirements

Not all hazardous environments are the same. A refinery tank farm may require Zone 1 equipment, while a logistics warehouse with occasional exposure may allow Zone 2 devices. Deploying the wrong classification can lead to regulatory violations and accidents.

Prevention Tip: Conduct a hazardous area assessment with a qualified safety engineer before selecting devices. Never assume one device fits all work zones.

3. Mixing Personal and Professional Usage

Allowing frontline workers to install personal apps or use devices for non-work activities introduces security vulnerabilities and compliance gaps. Consumer apps may bypass corporate security, leak sensitive data, or drain device resources needed for safety-critical functions.

Prevention Tip: Use Mobile Device Management (MDM) to restrict devices to approved applications and enforce zero-trust security policies.

4. Neglecting Maintenance and Recertification

Compliance is not permanent—certificates expire, seals degrade, and rugged cases can wear down under heavy use. Organizations that deploy devices but fail to schedule inspections and recertifications risk operating with compromised equipment.

Prevention Tip: Establish a structured maintenance and audit program. Log inspections, replace worn parts, and engage third-party auditors annually to stay compliant.

5. Undertraining Frontline Workers

Even with the best equipment, human error can undermine compliance. Workers may charge devices in restricted zones, ignore damaged seals, or use uncertified cables if not properly trained.

Prevention Tip: Provide ongoing training that covers safe handling, inspection procedures, and escalation protocols. Include compliance training in onboarding and refreshers annually.

6. Treating Compliance as a One-Time Task

Some companies see compliance as a checkbox to tick during deployment, then move on. In reality, compliance is a continuous, evolving process shaped by regulatory changes, technological updates, and environmental conditions.

Prevention Tip: Make compliance a core element of company culture. Regularly review new regulations, update mobile technology policies, and audit systems to ensure ongoing adherence.

Avoiding these common mistakes is as much about culture and process as it is about technology. Certified devices alone are not enough—compliance must be continuously managed, audited, and reinforced across people, processes, and tools.

Best Practices from Industry Leaders

Industry leaders like Conquest-Ex and others in rugged mobility emphasize that compliance must be embedded in every step of deployment.

Proven Best Practices

- Tailored solutions by industry: Oil and gas require different accessories than utilities or logistics.

- Certified rugged design: Devices built for shock, vibration, dust, and extreme temperatures.

- End-to-end ecosystem: Certified mounts, chargers, and accessories.

- Ongoing support: Compliance doesn’t end with purchase—support and recertification matter.

By following these best practices, organizations achieve both compliance and operational efficiency.

Future Trends in Hazardous Environment Compliance

The next generation of compliance will merge digital innovation with regulatory rigor.

- Zero-trust security models: Ensuring no device operates without continuous verification.

- AI-driven compliance monitoring: Automated detection of non-compliant usage.

- IoT integration: Real-time sensor data to support compliance reporting.

- Global harmonization: Efforts to align ATEX, IECEx, and NEC standards for multinational consistency.

Organizations that adopt these trends early will reduce risk while boosting productivity.

Understanding ATEX zones is vital for industrial safety. These zones classify areas by explosion risk, helping choose the right equipment to prevent hazards.

Conclusion

Deploying mobile technology in hazardous environments is no longer optional—it’s essential for modern, connected operations. However, every device must comply with hazardous environment regulations to protect workers, assets, and organizational reputation.

Compliance requires a multi-layered strategy: certified devices, proper training, strict MDM policies, and ongoing audits. When done correctly, mobile technology becomes a productivity multiplier that enhances safety rather than compromises it.

Looking to deploy mobile devices safely in hazardous environments?

Discover ATEX & IECEx-certified solutions designed for your industry. Contact us today to ensure compliance, protect your workforce, and unlock the full potential of rugged mobile technology.

Zone 1/Zone 2 Devices: Technology Trends for Risk Reduction highlight the latest innovations that enhance safety in hazardous areas, reduce risks, and ensure compliance with ATEX standards.

More Interesting Posts

How Conquest EX202 Enhances Operational Efficiency with Built-In Tools

Enhancing Worker Safety with Conquest EX201’s Satellite Communication

Explosion Proof Smartphones in Malaysia for Petrochemical Industry