IoT Integration: How Smart Devices Are Revolutionizing Hazardous Site Monitoring

IoT Integration: How Smart Devices Are Revolutionizing Hazardous Site Monitoring

In today’s industrial world, hazardous sites like oil rigs, chemical plants, and mining operations face complex challenges in safety, compliance, and operational efficiency. Monitoring these high-risk environments requires more than traditional tools—it demands intelligent systems capable of delivering real-time insights. This is where IoT integration: how smart devices are revolutionizing hazardous site monitoring comes into play. By combining cutting-edge technology with rugged, ATEX and IECEx-certified devices, organizations can ensure worker safety, improve operational efficiency, and reduce costs.

What Is IoT Integration in Hazardous Environments?

Internet of Things (IoT) integration refers to connecting devices, sensors, and systems to gather, process, and share data automatically. In hazardous environments, IoT connects smart devices such as rugged smartphones, wearable sensors, and environmental monitoring equipment to a centralized platform.

This integration allows safety managers and engineers to monitor critical parameters, including gas levels, temperature, pressure, and equipment health, in real time. Crucially, IoT solutions for hazardous sites must comply with strict ATEX and IECEx certifications, ensuring safe operation in potentially explosive atmospheres.

The Role of Smart Devices in Hazardous Site Monitoring

Smart devices play a pivotal role in IoT integration, acting as gateways to monitor, report, and respond to potential hazards.

- Explosion-proof smartphones act as central hubs, collecting data from wearable sensors and connected machinery.

- Real-time data capture enables immediate alerts for dangerous conditions, allowing rapid response and mitigation.

- Integration with AI and predictive analytics helps organizations anticipate equipment failures or environmental hazards before they occur, preventing accidents and downtime.

By combining rugged devices with smart sensors, IoT empowers organizations to monitor hazardous environments safely and efficiently.

Key Benefits of IoT-Enabled Hazardous Site Monitoring

1. Enhanced Worker Safety

IoT solutions ensure continuous monitoring of employees via wearable devices, location tracking, and environmental sensors. Alerts can be triggered instantly if workers enter dangerous zones, ensuring timely intervention and minimizing risks.

2. Real-Time Hazard Detection

Gas leaks, temperature fluctuations, and abnormal pressure readings can be detected immediately. Smart devices connected to IoT systems ensure that safety teams are alerted in real time, preventing incidents before they escalate.

3. Improved Compliance & Reporting

Maintaining accurate safety logs and compliance records is simplified with IoT-enabled digital reporting. Automated data collection reduces human error and ensures adherence to regulatory standards, providing peace of mind for site managers and regulators.

4. Operational Efficiency & Cost Reduction

IoT integration streamlines communication between teams, reduces downtime, and allows predictive maintenance of critical machinery. By identifying hazards before they cause damage, organizations can save significant operational costs.

Industry Applications of IoT Integration

-

Oil & Gas

Remote monitoring of oil rigs ensures real-time hazard detection, emergency response coordination, and safe operational workflows.

-

Chemical Plants

IoT-enabled sensors detect chemical leaks and unsafe conditions, helping prevent accidents and environmental hazards.

-

Mining & Logistics

Wearable devices track workers’ locations, ensuring safety in high-risk areas, while connected machinery monitors operational efficiency.

-

Manufacturing

Predictive maintenance of industrial equipment reduces downtime and prevents catastrophic failures, safeguarding both personnel and production schedules.

Future Trends in IoT for Hazardous Environments

As industries continue to prioritize safety, efficiency, and predictive capabilities, the future of IoT integration: how smart devices are revolutionizing hazardous site monitoring is becoming increasingly innovative. Smart de\vices and connected systems are not only detecting hazards in real time but also anticipating them before they become critical threats. Here are the key trends shaping the next generation of hazardous site monitoring:

1. AI-Powered Predictive Analytics

Artificial intelligence (AI) is transforming the way hazardous sites are monitored. By analyzing data collected from sensors, wearables, and smart devices, AI algorithms can identify patterns and predict potential risks. For example, subtle fluctuations in gas levels or machinery vibration can trigger alerts before an accident occurs. This proactive approach reduces downtime, enhances worker safety, and ensures continuous operations.

2. Edge Computing for Faster Response

Traditional cloud-based IoT systems can sometimes introduce latency in critical environments. Edge computing addresses this by processing data locally on-site, close to the sensors and devices. This enables instant decision-making and immediate alerts for hazards, allowing safety teams to act faster and prevent accidents in explosive or high-risk areas.

3. 5G-Enabled IoT Communication

The rollout of 5G networks is revolutionizing IoT communication on hazardous sites. Ultra-fast, low-latency connectivity ensures that data from multiple devices—ranging from wearables to rugged ATEX-certified smartphones—is transmitted and analyzed in real time. This enhanced connectivity allows for seamless integration across remote and expansive industrial sites.

4. Smart Wearables and Biometric Monitoring

Wearable technology is evolving beyond simple tracking devices. Modern wearables equipped with biometric sensors can monitor workers’ heart rates, fatigue levels, and exposure to hazardous conditions. Coupled with IoT platforms, these devices alert managers if an employee is at risk, enhancing personal safety while providing valuable health data.

5. Integration with Digital Twins

Digital twin technology is emerging as a key trend for hazardous site monitoring. By creating a virtual replica of the site, organizations can simulate different scenarios, identify potential hazards, and optimize safety protocols. IoT devices feed real-time data into the digital twin, providing actionable insights and predictive modeling for better risk management.

6. Sustainability and Energy-Efficient IoT

Future IoT devices are being designed with energy efficiency and sustainability in mind. Low-power sensors, solar-powered devices, and optimized data transmission protocols reduce the environmental footprint while maintaining high safety standards. This ensures that hazardous site monitoring aligns with corporate responsibility goals and regulatory standards.

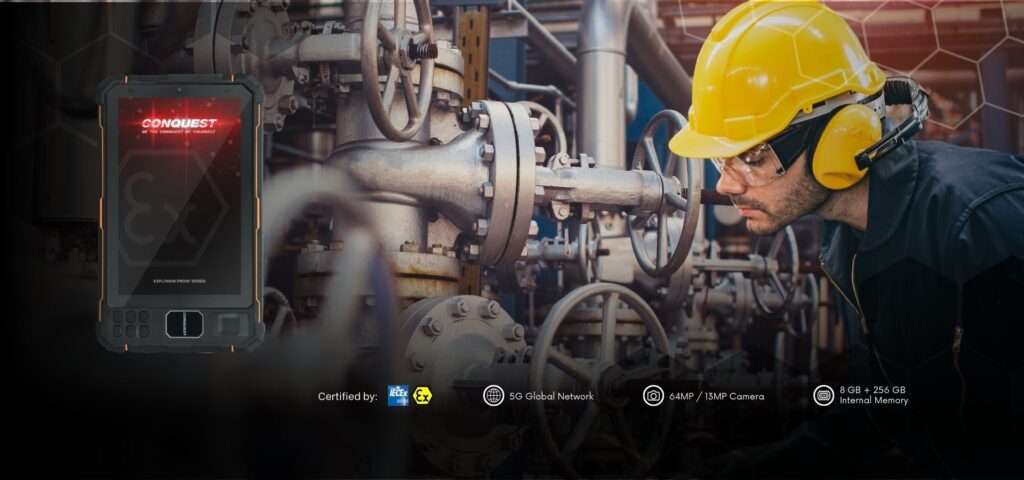

Why Choose Conquest for IoT Integration?

When it comes to IoT integration: how smart devices are revolutionizing hazardous site monitoring, selecting the right partner is critical. Conquest specializes in providing rugged, ATEX and IECEx-certified smartphones and IoT-enabled solutions specifically designed for extreme industrial environments. Here’s why Conquest stands out as the trusted choice for hazardous site monitoring:

1. ATEX & IECEx Certification for Maximum Safety

Conquest devices are fully certified for use in explosive atmospheres under ATEX and IECEx standards. This certification ensures that every smartphone, wearable, and sensor can operate safely in potentially hazardous environments such as chemical plants, oil rigs, and mining sites. By choosing Conquest, organizations can deploy IoT solutions without compromising on safety compliance.

2. Rugged Devices Built for Extreme Conditions

Hazardous sites are unforgiving environments, often involving extreme temperatures, dust, moisture, or mechanical shocks. Conquest rugged smartphones are engineered to withstand these harsh conditions, ensuring uninterrupted performance. These devices serve as reliable IoT hubs, collecting and transmitting critical data even in the most challenging scenarios.

3. Seamless IoT Integration

Conquest devices are designed to seamlessly integrate with IoT sensors, wearables, and analytics platforms. From real-time monitoring of gas levels and temperature fluctuations to predictive maintenance and equipment tracking, Conquest ensures that all data streams are connected and actionable. This integration allows companies to identify hazards before they escalate and make informed operational decisions.

4. Customizable Solutions for Industry Needs

Every industrial environment has unique challenges. Conquest offers customizable IoT solutions tailored to specific industry requirements, whether it’s oil and gas, chemical processing, mining, or logistics. Organizations can configure devices, software, and monitoring systems to meet their exact operational needs, ensuring maximum efficiency and safety.

5. Proven Track Record & Case Studies

Conquest has a strong history of successfully deploying IoT-enabled devices in hazardous industries worldwide. Numerous case studies demonstrate measurable improvements in worker safety, operational efficiency, and regulatory compliance. Companies choosing Conquest gain access to this expertise, enabling faster implementation and higher ROI for their IoT initiatives.

6. Ongoing Support & Updates

Conquest doesn’t just provide devices—it partners with organizations for long-term success. Continuous software updates, technical support, and guidance on IoT best practices ensure that your hazardous site monitoring solutions remain cutting-edge, reliable, and fully compliant over time.

Understanding ATEX zones is vital for industrial safety. These zones classify areas by explosion risk, helping choose the right equipment to prevent hazards.

Conclusion

IoT integration: how smart devices are revolutionizing hazardous site monitoring is no longer a futuristic concept—it is the present reality for industries prioritizing safety and operational excellence. Smart devices, connected sensors, and real-time data analytics empower organizations to anticipate hazards, protect workers, and optimize performance.

Ready to transform your hazardous site monitoring with IoT-enabled smart devices? Discover Conquest’s ATEX & IECEx-certified rugged smartphones and solutions today. Contact us for a free consultation or demo and take the first step toward safer, smarter operations.

Zone 1/Zone 2 Devices: Technology Trends for Risk Reduction highlight the latest innovations that enhance safety in hazardous areas, reduce risks, and ensure compliance with ATEX standards.

More Interesting Posts

How Conquest EX202 Enhances Operational Efficiency with Built-In Tools

Enhancing Worker Safety with Conquest EX201’s Satellite Communication

Explosion Proof Smartphones in Malaysia for Petrochemical Industry