Mobile Device Innovations: Enhancing Communication in High-Risk Zones

Communication is the lifeline of every industry, but in high-risk environments—such as oil rigs, chemical plants, or mining zones—it becomes a matter of safety and survival. Over the past decade, mobile device innovations have transformed how people connect, share information, and respond in hazardous areas. From explosion-proof smartphones to real-time data systems, these advancements have made communication faster, safer, and more reliable.

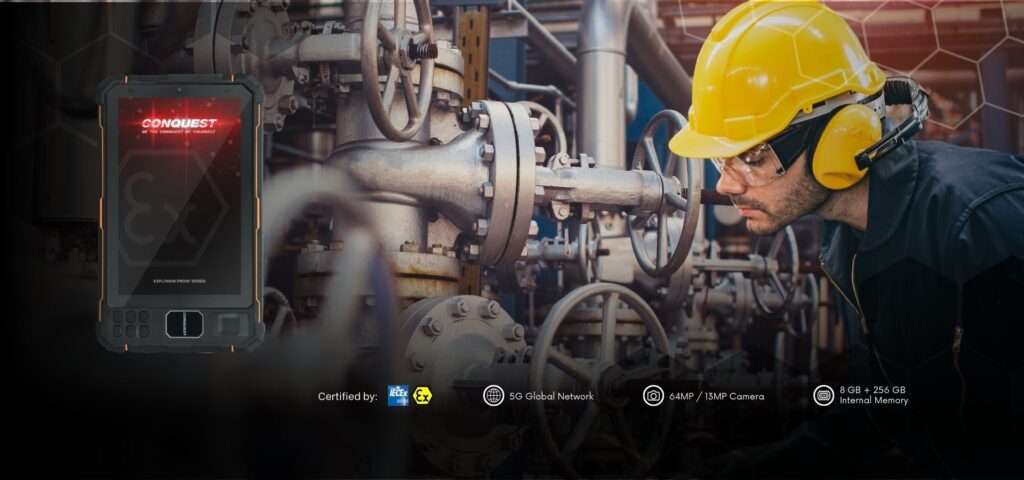

Today’s rugged and intrinsically safe mobile devices are not just tools; they are safety enablers. Certified to withstand explosions, extreme heat, and environmental stress, they ensure workers stay connected without compromising safety standards. Companies like Conquest have been at the forefront of these breakthroughs—engineering devices that combine durability with intelligence to empower frontline workers worldwide.

The Evolution of Mobile Communication in High-Risk Environments

A few decades ago, communication in hazardous environments relied on analog radios and hardwired intercoms. These systems were functional but limited, often prone to interference, and lacked real-time data capabilities. The evolution of rugged mobile devices and smart connectivity has changed that landscape entirely.

Modern innovations—like 5G-enabled, ATEX and IECEx-certified smartphones—allow instant voice, video, and data transmission even in explosive atmospheres. These devices are engineered with precision to eliminate ignition risks while maintaining full smart functionalities. As industries became more digitized, the demand for mobile communication solutions that could operate safely in extreme conditions skyrocketed.

Core Challenges of Communication in High-Risk Zones

Operating in hazardous environments presents several communication challenges:

- Safety Compliance – Devices must meet stringent international standards like ATEX, IECEx, or IP ratings to prevent sparks or heat emissions that could ignite flammable gases or dust.

- Environmental Durability – High temperatures, dust, moisture, and vibration can damage standard electronics, making rugged design a necessity.

- Signal Interference – Metal structures and underground locations often weaken connectivity.

- Battery Reliability – Continuous use in remote areas requires extended battery life without compromising safety.

- Data Security – In critical zones, maintaining secure communication channels is essential to protect sensitive operational data.

Overcoming these challenges requires a blend of engineering innovation, material science, and smart software integration.

The Rise of Intrinsically Safe Mobile Devices

One of the most critical breakthroughs in mobile technology for high-risk zones is the intrinsically safe device. These are engineered to prevent any form of ignition, even under fault conditions.

Key Features Include:

- Explosion-proof casings

- Sealed connectors and ports

- Anti-static materials

- Low voltage and current circuitry

- Certification under ATEX and IECEx standards

These devices have become indispensable for workers in oil refineries, gas exploration sites, chemical factories, and other hazardous locations.

Companies like Conquest have redefined safety with smartphones that merge intrinsic safety with powerful computing performance—delivering 8GB RAM, 5G connectivity, and integrated safety modules all within a rugged, compliant frame.

Understanding ATEX zones is vital for industrial safety. These zones classify areas by explosion risk, helping choose the right equipment to prevent hazards.

How Rugged Devices Enhance Real-Time Operations

Communication in high-risk zones isn’t just about talking—it’s about data-driven decision-making. Modern rugged devices now support multiple functions:

- Real-Time Monitoring – Through IoT integration, sensors relay live environmental data such as gas levels, temperature, and pressure to central systems.

- Visual Communication – High-resolution cameras enable video inspections and live-streaming from hazardous zones.

- Team Coordination – Push-to-talk and group messaging apps enhance coordination between on-site and off-site teams.

- Digital Workflows – Workers can access digital manuals, maintenance records, and reporting tools on the go.

The result is a connected workforce that operates more efficiently, with improved safety outcomes and reduced downtime.

5G, Edge Computing, and IoT Integration: How Smart Devices Are Revolutionizing Hazardous Site Monitoring

The combination of 5G connectivity, edge computing, and IoT integration is redefining how industries manage safety and efficiency in hazardous zones. This evolution—captured in the phrase “IoT Integration: How Smart Devices Are Revolutionizing Hazardous Site Monitoring”—reflects a global shift toward smarter, data-driven operations.

Ultra-fast 5G networks now enable instant communication between devices, control centers, and field operators. With IoT sensors embedded across critical equipment, real-time data flows seamlessly to mobile devices, empowering workers to make faster, safer decisions. Edge computing processes this data locally on rugged devices like the Conquest EX201, ensuring immediate insights even when external connectivity is limited.

These innovations allow industries to predict equipment failures, detect gas leaks, and respond to emergencies before they escalate. In essence, IoT integration has turned every rugged smartphone into a powerful monitoring hub—transforming communication from simple voice exchange into a proactive safety management system.

Design Innovations That Empower Workers

Modern rugged devices are more than just tough—they’re smartly designed to meet the real-world demands of frontline operators in challenging and hazardous environments. Every design choice—from the materials used to the software interface—plays a vital role in supporting safety, comfort, and reliability.

- Extended Battery Life: Long-lasting power ensures uninterrupted communication during long shifts, even in remote or high-risk areas.

- Ergonomic Design: Devices are built for gloved use, making them practical and safe for industrial operations where dexterity is limited.

- Customizable Interfaces: Companies can configure buttons for emergency alerts, data capture, or one-touch communication.

- Modular Attachments: Add-ons such as high-intensity flashlights, barcode scanners, or thermal cameras improve device functionality in complex work settings.

Beyond design, maintaining the safety integrity of these rugged devices is equally crucial. Following Best Practices for Maintaining ATEX-Certified Equipment ensures that every mobile device continues to perform safely and reliably over time. Regular inspections, firmware updates, and compliance checks help extend device lifespan and prevent malfunctions in volatile environments.

Conquest’s engineering philosophy reflects this commitment to both durability and long-term safety. Each device is built and supported with strict adherence to maintenance and compliance standards—empowering workers to operate confidently with technology that’s as resilient as they are.

Real-World Applications Across Industries

1. Oil and Gas

Workers use explosion-proof smartphones to monitor pipelines, capture data, and communicate instantly during operations. Devices ensure safety while maintaining high efficiency in flammable environments.

2. Mining

Deep underground, reliable communication is essential. Rugged mobile devices allow geologists and miners to exchange live updates, detect hazards, and coordinate evacuations.

3. Chemical Manufacturing

In volatile chemical plants, mobile devices like Conquest EX101 provide a safe and efficient communication network, supporting automation and digital inspection tools.

4. Logistics and Warehousing

With durable design and strong connectivity, rugged devices streamline tracking, inventory control, and field coordination in high-pressure supply chains.

5. Emergency and Rescue Operations

During disasters, robust mobile devices with GPS and satellite communication capabilities ensure continuous coordination and location tracking.

The Role of AI and Predictive Analytics

Artificial Intelligence is revolutionizing mobile communication in high-risk zones. Integrated AI systems analyze data from connected sensors to predict equipment failures or detect environmental threats. This helps organizations prevent incidents before they occur.

Rugged mobile devices now function as intelligent nodes within an Industrial IoT ecosystem, turning every worker into a data source for smarter and safer operations.

Sustainability and Future Outlook

As industries move toward sustainability, future mobile device innovations will emphasize eco-friendly materials, longer lifecycle management, and energy-efficient designs.

With rapid advancements in battery technology and AI-driven diagnostics, devices will soon self-monitor their health, alerting teams before performance drops. Conquest’s commitment to continuous innovation is paving the way for this sustainable, intelligent communication era.

Choosing the Right Device for Hazardous Environments

Selecting the right communication device involves evaluating:

- Certification compliance (ATEX, IECEx)

- Durability under physical and environmental stress

- Connectivity options (5G, Wi-Fi, satellite)

- Battery longevity and hot-swappable features

- Manufacturer reliability and aftersales support

A trusted brand like Conquest combines all these attributes with client-focused customization, ensuring every device fits the operational needs of your environment.

Conclusion: Communication that Saves Lives

In high-risk zones, communication is more than convenience—it’s a safety imperative. The evolution of mobile device technology has redefined how teams collaborate, respond, and stay secure in challenging environments. Rugged and intrinsically safe mobile devices have made it possible to achieve seamless connectivity without compromising safety.

As innovation continues, companies like Conquest are leading the way with solutions that integrate durability, intelligence, and adaptability. These devices are not only tools but vital partners in ensuring that every worker returns home safely.

Enhance your communication systems with Conquest’s ATEX and IECEx-certified smartphones—engineered for safety, durability, and smart performance in the toughest environments. Whether in oil and gas, logistics, or chemical production, Conquest delivers customized, reliable, and future-ready solutions that keep your team connected and protected.

Frequently Asked Questions (FAQs)

- What are high-risk zones in industrial environments?

High-risk zones are areas prone to explosions, chemical leaks, or electrical hazards, such as oil rigs, refineries, or chemical plants. - What makes a mobile device “intrinsically safe”?

It means the device is engineered to prevent ignition even in explosive atmospheres through special circuitry and materials. - Why is ATEX or IECEx certification important?

These certifications guarantee that the device meets international safety standards for use in hazardous environments. - Can rugged devices support 5G and smart features?

Yes. Modern rugged smartphones like the Conquest EX201 integrate 5G, AI, and IoT features while remaining explosion-proof. - Are these devices suitable for extreme temperatures?

Yes. Intrinsically safe smartphones are tested to operate in extreme heat, cold, dust, and moisture. - How do rugged devices enhance safety?

They enable real-time communication, emergency alerts, and monitoring systems that help prevent accidents. - Are rugged smartphones customizable?

Brands like Conquest offer customization options such as added memory, special buttons, or modular attachments. - How does Conquest support industries after purchase?

Conquest provides 24/7 professional support, continuous updates, and tailored service plans to ensure uninterrupted operation.

More Interesting Posts

How Conquest EX202 Enhances Operational Efficiency with Built-In Tools

Enhancing Worker Safety with Conquest EX201’s Satellite Communication

Explosion Proof Smartphones in Malaysia for Petrochemical Industry