Technical Deep Dive: How Intrinsically Safe Phones Prevent Explosions

Technical Deep Dive: How Intrinsically Safe Phones Prevent Explosions

In industrial environments like oil refineries, chemical plants, and mining sites, a single spark can lead to catastrophic explosions. The risk of ignition from electronic devices is a major safety concern. This is where intrinsically safe phones come in — devices specially engineered to operate safely in explosive atmospheres without igniting flammable gases, vapours, or dust.

In this deep dive, we’ll explore how these rugged devices prevent explosions, the standards behind them, and why they’re vital to modern industrial communication — especially in environments where reliability and safety cannot be compromised.

Understanding Intrinsic Safety: The Science Behind Explosion Prevention

Intrinsic safety (IS) is a design philosophy that ensures electrical equipment does not release enough energy to cause ignition in hazardous environments. Rather than enclosing explosions (like explosion-proof housings do), IS prevents ignition at its source.

An intrinsically safe phone is engineered so that its electrical and thermal energy levels are always below the threshold needed to ignite hazardous materials. This means that even in the event of a fault — such as a short circuit or battery failure — the device remains safe.

The Principle in Simple Terms

Every electronic device carries a risk of generating heat or sparks. Intrinsic safety eliminates that risk by:

- Limiting power and voltage within circuits.

- Controlling surface temperature to remain below ignition levels.

- Using certified safety barriers and protective components.

This makes intrinsically safe phones the safest communication tools for explosive atmospheres.

Certifications Demystified: ATEX, IECEx, and Global Standards for Safety Devices

Not all “rugged” phones are safe for explosive zones. True intrinsic safety requires international certification and compliance with stringent global standards.

ATEX Certification (Europe)

ATEX stands for Atmosphères Explosibles, a European directive that ensures equipment used in explosive atmospheres meets strict safety requirements. Devices with ATEX certification have been thoroughly tested to operate safely around flammable gases and combustible dust.

IECEx Certification (Global)

IECEx is an internationally recognised certification system for equipment used in explosive environments. It aligns closely with ATEX but provides a globally standardised framework, ensuring that devices are tested for both electrical safety and thermal compliance.

Together, these certifications form the backbone of trust for industries operating in high-risk environments.

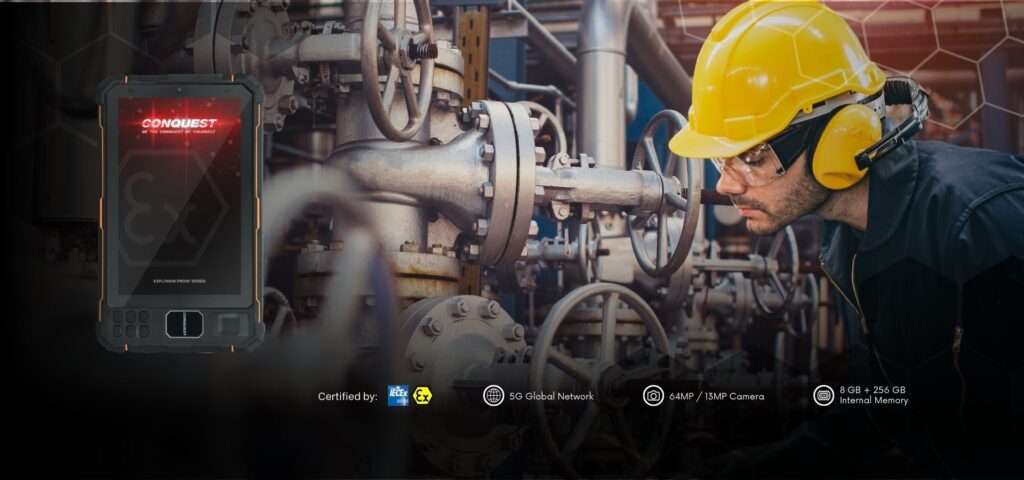

Conquest smartphones are both ATEX and IECEx certified, offering verified assurance that they meet the world’s most demanding standards for safety, reliability, and performance in hazardous zones.

Inside an Intrinsically Safe Phone: Key Engineering Features

To understand how intrinsically safe phones prevent explosions, let’s break down their internal design.

1. Energy Limitation

All circuits inside the device are designed to restrict current and voltage. This ensures that even if a fault occurs, there’s not enough power to generate an ignition source.

2. Temperature Control

Each component is carefully selected to operate within strict temperature limits. The phone’s surface and internal parts are engineered to stay cool even under heavy use, preventing any chance of a heat-induced ignition.

3. Protective Barriers

Intrinsic safety barriers isolate hazardous areas from potential energy surges. These barriers protect both the user and the surrounding environment from electrical discharge.

4. Encapsulation and Sealing

Critical components are encapsulated in protective resin or sealed against gas and dust ingress. This not only improves safety but also enhances durability and water resistance — key features of Conquest’s rugged designs.

5. Antistatic Materials

Static electricity can ignite flammable gases. That’s why IS phones use antistatic enclosures and materials that dissipate charge safely.

6. Battery Design

Batteries are one of the most sensitive elements in any mobile device. Intrinsically safe phones feature custom-designed batteries that limit energy output, include thermal cutoffs, and prevent overcharging.

Why Ruggedness and Intrinsic Safety Go Hand in Hand

In real-world industrial environments, phones face extreme conditions — impact, vibration, moisture, and dust. Intrinsically safe phones must therefore combine mechanical toughness with electrical safety.

A rugged intrinsically safe smartphone is built to handle physical stress while maintaining safety compliance. Features include:

- Reinforced housings to withstand drops.

- Ingress protection (IP65 or higher) for dust and water resistance.

- Corrosion-resistant materials for chemical exposure.

This makes them ideal for frontline workers who need durable communication tools that won’t compromise safety — even in explosive zones.

Preventing Ignition: The Role of Electronics Design

An explosion requires three elements: fuel, oxygen, and an ignition source (spark or heat). Industrial facilities often can’t eliminate the first two — gases and air are part of the environment. The goal is to eliminate the third.

Intrinsic safety design ensures no part of the phone — from its screen to its battery — can become that ignition source. Engineers achieve this by:

- Limiting voltage and current.

- Designing printed circuit boards (PCBs) with spatial separation to prevent arcing.

- Using fail-safe components that shut down during abnormal operation.

Even if the phone is damaged, dropped, or exposed to high temperatures, its internal systems are structured to remain fail-safe.

Testing and Validation: Ensuring True Intrinsic Safety

Before certification, intrinsically safe phones undergo rigorous testing that simulates real-world hazards. This includes:

- Spark ignition tests to confirm no ignition at maximum energy output.

- Thermal testing to ensure components stay within safe temperature ranges.

- Drop and vibration tests to verify durability in harsh environments.

Only after passing these assessments can a device earn its ATEX or IECEx certification.

Conquest’s smartphones go through multi-stage verification, ensuring that every model provides reliable communication without risk — even in the most volatile zones.

Beyond Safety: Modern Capabilities in Intrinsically Safe Phones

Historically, safety-certified devices sacrificed performance. That’s no longer the case. Today’s intrinsically safe phones deliver modern mobile performance while maintaining strict safety standards.

Conquest’s devices, for example, offer:

- 5G connectivity for fast, real-time communication.

- High-capacity storage and RAM for industrial applications.

- Integrated high-lumen flashlights and cameras for documentation in low-light zones.

- Customisable functions to meet specific operational needs.

These innovations prove that safety and performance can coexist seamlessly — empowering workers while ensuring compliance.

Ensuring mobile technology compliance in hazardous environments is essential for safety and regulatory adherence. Choosing certified devices and following proper operational protocols helps prevent accidents and equipment failures. Learn more about Hazardous Environment Regulations: Compliance Tips for Mobile Technology to keep your operations safe and compliant.

The Future of Intrinsic Safety: Smarter, Connected, and Safer

As industrial operations become increasingly digital, the demand for intrinsically safe smart devices is growing. The next generation of IS phones will integrate:

- IoT compatibility for remote monitoring.

- AI-driven diagnostics for predictive maintenance.

- Enhanced location tracking for worker safety.

- Custom interfaces tailored for industry-specific applications.

Manufacturers like Conquest are leading this evolution — bridging the gap between safety technology and digital innovation.

Why Choose Conquest for Intrinsically Safe Communication

Conquest stands out for one clear reason: safety without compromise.

Their ATEX & IECEx certified smartphones are designed to perform under pressure — delivering seamless communication, uncompromised durability, and total peace of mind.

When it comes to industrial technology, reliability isn’t the only factor that matters. Increasingly, organisations are also evaluating the Environmental Impact of Industrial Mobile Devices: What Companies Should Know is that sustainable design, energy efficiency, and long product life cycles play a crucial role in reducing waste and improving operational responsibility. Conquest embraces this approach by engineering rugged smartphones that last longer, require fewer replacements, and support a more sustainable industrial ecosystem.

When you choose Conquest, you get:

- Proven compliance with international safety standards.

- Rugged performance built for the harshest environments.

- Tailored features to meet your unique operational needs.

- Continuous support to ensure uninterrupted operations.

Whether your team works in oil & gas, logistics, manufacturing, or chemical processing, Conquest ensures your communication is smart, safe, and sustainable — empowering your workforce while minimising environmental impact.

Conclusion: Safety, Innovation, and Reliability in Every Device

Intrinsically safe phones represent a vital intersection of engineering precision and life-saving safety. They ensure that frontline workers can stay connected — without putting themselves or their environments at risk.

As industries evolve, the need for devices that balance performance and safety will only grow. Conquest’s ATEX and IECEx-certified smartphones lead this transformation — offering durable, intelligent, and safe communication solutions for hazardous environments worldwide.

Experience the perfect combination of safety, performance, and reliability. Explore Conquest’s range of intrinsically safe, ATEX & IECEx-certified smartphones engineered for hazardous environments.

Visit conquest to discover how Conquest can redefine safety and efficiency in your operations.

Avoid common pitfalls with IECEx-approved devices to ensure safety and compliance in hazardous environments. Learn about proper device selection, maintenance, and usage in 5 Common Mistakes to Avoid with IECEx-Approved Devices.

FAQs About Intrinsically Safe Phones

- What is an intrinsically safe phone?

An intrinsically safe phone is a device engineered to operate safely in explosive atmospheres by limiting electrical and thermal energy below ignition levels. - How do intrinsically safe phones prevent explosions?

They prevent explosions by controlling voltage, temperature, and current to eliminate sparks or heat that could ignite flammable gases or dust. - What certifications should I look for?

Look for ATEX (European) and IECEx (International) certifications — they confirm compliance with global safety standards. - Are intrinsically safe phones the same as explosion-proof phones?

No. Explosion-proof phones contain potential explosions inside the device, while intrinsically safe phones prevent ignition from happening at all. - Can intrinsically safe phones still have modern features?

Yes. Today’s models, like those from Conquest, include 5G connectivity, high-resolution cameras, and rugged durability while remaining fully certified. - Where are intrinsically safe phones used?

They are used in oil & gas sites, chemical plants, refineries, mines, and other hazardous environments with flammable gases or dust. - How can I verify if a phone is truly certified?

Check for official ATEX/IECEx markings on the device and certification documentation from recognized testing bodies. - Why choose Conquest over other manufacturers?

Conquest combines intrinsic safety with cutting-edge performance, customer-focused design, and 24/7 professional support, making them a trusted partner for industrial safety communication.

More Interesting Posts

How Conquest EX202 Enhances Operational Efficiency with Built-In Tools

Enhancing Worker Safety with Conquest EX201’s Satellite Communication

Explosion Proof Smartphones in Malaysia for Petrochemical Industry