Zone 1/Zone 2 Devices: Technology Trends for Risk Reduction

In industries where safety is non-negotiable, the right technology can mean the difference between smooth operations and catastrophic risk. From oil rigs to chemical plants, hazardous zones demand devices that are designed not just for performance but for survival in extreme conditions. That’s where Zone 1/Zone 2 devices come in — specialized, certified, and engineered to reduce risk while boosting efficiency.

In this blog, we’ll explore what these devices are, why they matter, and the key technology trends shaping their future.

What Are Zone 1 and Zone 2 Devices?

Understanding Hazardous Zones

Hazardous areas are classified based on the likelihood of explosive atmospheres being present.

- Zone 1: An environment where flammable gases, vapors, or dust are likely to occur during normal operations.

- Zone 2: An area where such hazards are less likely, and if they do occur, they exist only for a short time.

Why Device Certification Matters (ATEX & IECEx)

Not every rugged device qualifies for use in these zones. Devices must carry international safety certifications like ATEX (Europe) or IECEx (global) to ensure they won’t trigger explosions. Certified Zone 1/Zone 2 devices undergo rigorous testing for durability, thermal stability, and spark prevention, making them indispensable in hazardous workplaces.

Why Zone 1/Zone 2 Devices Are Essential for Risk Reduction

In industries such as oil & gas, chemical manufacturing, mining, and utilities, risk reduction is the number one priority. Any spark, overheating battery, or faulty device can cause catastrophic consequences in hazardous zones. This is why Zone 1/Zone 2 devices: technology trends for risk reduction are more than just a technological upgrade — they are a critical investment in safety, compliance, and business continuity.

1. Enhanced Worker Safety

Zone 1/Zone 2 devices are designed with explosion-proof enclosures, intrinsically safe circuits, and thermal stability that prevent ignition sources from triggering an accident. Workers can use smartphones, tablets, and scanners with confidence in high-risk environments, knowing the devices are engineered to safeguard them.

2. Compliance with Global Standards

International regulations such as ATEX (Europe) and IECEx (global) mandate strict requirements for operating devices in hazardous zones. Using uncertified equipment can lead to violations, penalties, and legal risks. Certified Zone 1/Zone 2 devices ensure full compliance while reducing the burden on organizations to constantly monitor safety gaps.

3. Real-Time Risk Monitoring

Modern Zone 1/Zone 2 devices: technology trends for risk reduction integrate sensors, IoT connectivity, and AI-driven apps that allow real-time monitoring of gas levels, temperature changes, and environmental conditions. By alerting teams before hazards escalate, these devices play a proactive role in preventing accidents.

4. Operational Continuity in Hazardous Environments

Without proper communication and monitoring tools, operations in refineries, mines, or chemical plants can grind to a halt. Zone 1/Zone 2 devices support continuous workflows, instant communication, and data transfer in environments where downtime could cost millions of dollars.

5. Cost Efficiency and Long-Term Value

While investing in certified devices may seem costly initially, they reduce the risk of accidents, prevent regulatory fines, and minimize downtime. Additionally, multifunctional Zone 1/Zone 2 devices — equipped with cameras, scanners, and communication tools — eliminate the need for multiple gadgets, lowering long-term costs.

6. Trust and Confidence for Employees

When workers know they are equipped with certified, reliable devices, their confidence and productivity improve. Risk reduction is not only about technology but also about empowering people to perform their tasks effectively without constant fear of accidents.

In short, Zone 1/Zone 2 devices: technology trends for risk reduction are transforming safety strategies across hazardous industries. They combine certification, rugged design, and smart connectivity to create safer, more efficient workplaces.

Technology Trends Shaping Zone 1/Zone 2 Devices in 2025 and Beyond

-

Explosion-Proof Design Enhancements

Next-generation Zone 1/Zone 2 devices are engineered with reinforced enclosures, improved sealing, and ruggedized exteriors to withstand extreme heat, dust, and impact.

-

Integration with 5G & IoT

High-speed 5G connectivity and IoT integration enable real-time monitoring, predictive analytics, and seamless communication across large industrial sites.

-

AI-Powered Safety Applications

Artificial Intelligence is being embedded into devices to detect risks earlier. For example, AI apps can analyze gas sensor data and alert teams before conditions turn critical.

-

Multi-Functional Devices

Today’s Zone 1/Zone 2 smartphones double as scanners, cameras, flashlights, and communication tools — reducing the need for multiple gadgets and lowering costs.

-

Battery Innovations

Safe, long-lasting batteries with built-in thermal protection are a top priority. These advancements ensure devices run longer without overheating or sparking risks.

Industry Use Cases for Zone 1/Zone 2 Devices

-

Oil & Gas

Field workers rely on certified smartphones and tablets for live communication, inspection reporting, and safety alerts in offshore rigs and refineries.

-

Chemical Manufacturing

Hazard alerts, compliance documentation, and real-time safety monitoring are handled seamlessly with rugged, certified devices.

-

Logistics & Railways

From tracking cargo to ensuring worker safety in storage yards, Zone 1/Zone 2 devices provide reliable mobility solutions.

-

Mining & Utilities

In underground mines or high-voltage utility sites, rugged devices withstand harsh conditions while keeping workers connected and protected.

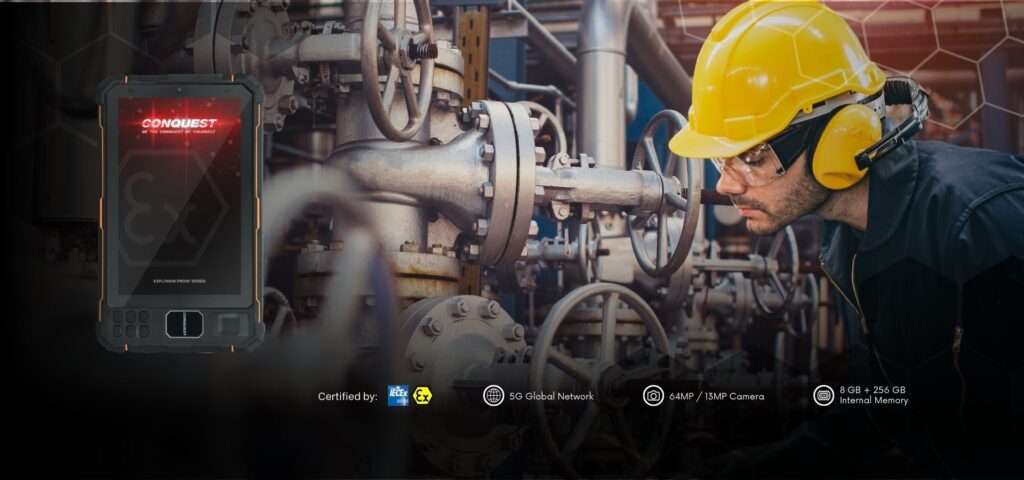

How Conquest is Redefining Safety with Zone 1/Zone 2 Devices

Conquest has positioned itself as a leader in explosion-proof technology with a strong lineup of ATEX & IECEx-certified smartphones.

- Flagship models: EX101, EX201, and EX202

- Certifications: Fully compliant with Zone 1/Zone 2 safety standards

- Customizable features: Options for storage, cameras, flashlight modules, and more

- Trusted by industry leaders: Conquest devices are used by China National Petroleum, ChemChina, China Railway, and other global enterprises

- Aftersales excellence: 24/7 technical support and professional services ensure clients stay operational without downtime

By combining ruggedness, safety, and smart technology, Conquest delivers devices that are more than tools — they are lifelines in hazardous industries.

Future Outlook of Zone 1/Zone 2 Devices

The future of intrinsically safe devices is about intelligence and integration. Expect to see:

- AI-driven predictive analytics for hazard prevention

- Stronger integration with enterprise mobility platforms

- More multifunctionality in a single device

- Wider adoption across industries as safety standards tighten globally

Zone 1/Zone 2 devices are no longer optional. They are becoming core business assets for safety-first organizations.

Understanding ATEX zones is vital for industrial safety. These zones classify areas by explosion risk, helping choose the right equipment to prevent hazards.

Conclusion

Zone 1/Zone 2 devices are essential for protecting workers, ensuring compliance, and reducing operational risks in hazardous environments. With innovations like 5G connectivity, AI applications, rugged explosion-proof designs, and advanced battery safety, these devices are set to transform how industries approach workplace safety.

Conquest is at the forefront of this transformation, offering certified, innovative, and reliable solutions that keep workers safe while empowering businesses to operate smarter.

Call to Action

Ready to protect your workforce with next-generation Zone 1/Zone 2 devices?

Contact Conquest today and discover how our certified smartphones can help your business reduce risks and improve efficiency in hazardous environments.

More Interesting Posts

How Conquest EX202 Enhances Operational Efficiency with Built-In Tools

Enhancing Worker Safety with Conquest EX201’s Satellite Communication

Explosion Proof Smartphones in Malaysia for Petrochemical Industry